The big picture - at the end of the shift

Data is good, real time would be better

Collecting data is only half the battle. But the second half of the rent is usually the one that causes the most problems. Of course data is generated in your production and of course you collect it. But often:

- data entry is delayed by manual activities

- media disruptions make data entry more difficult

- duplicate data entry efforts take up valuable time

- errors creep into the target systems during manual data transfer.

All of this makes the evaluation of your data unnecessarily time-consuming and prevents real-time transparency of your production processes.

The big picture - in real time

Increase your responsiveness with real-time data collection in weasl

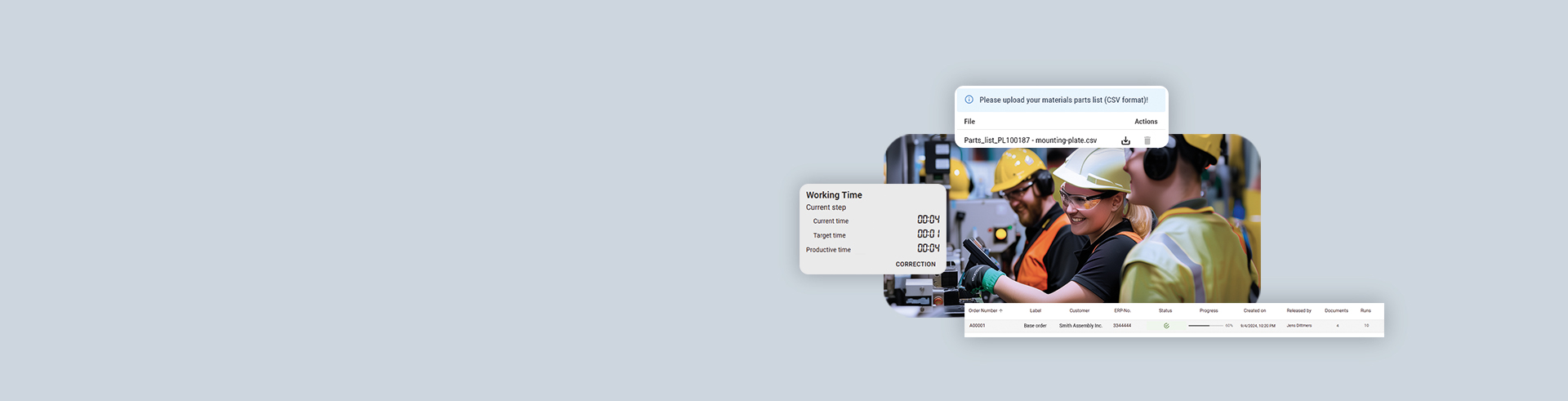

Avoid unnecessary detours: Capture production-relevant data where it is generated - with weasl without wasting time, duplication of effort and risk of error. weasl makes it possible to:

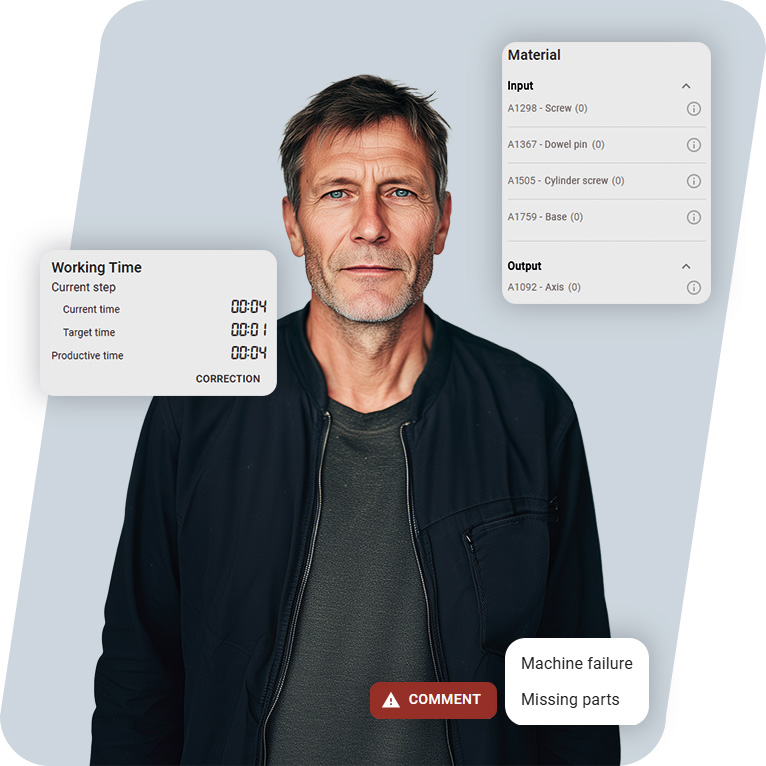

- report malfunctions such as machine failures or missing parts directly from the work step

- record process and quality data directly in the process

- track productive times precisely and correct working times if necessary

- track and record material - from parts lists to incoming material and outgoing material through to batches.

Increased transparency, reduced workload -

for you & your workers

weasl gives you real-time data transparency on the status quo of your manual production and assembly processes. Save your workers additional walking distances and documentation effort and benefit from

- automatic collection of information and input values

- optimal data exchange thanks to seamless integration into your existing infrastructure

- less downtime thanks to direct fault detection and fast troubleshooting

- optimal conditions for data analysis and continuous improvement processes

"The longer we work with weasl, the more interesting the product becomes within the company. We want to expand weasl further and develop it into a permanent fixture in our day-to-day production."

André Hink

Head of Prototype Shop and Production

Let's talk about your options.

Exploit the potential of your data efficiently and create transparency about your production processes with weasl. In a personal, non-binding consultation we

- take time for your needs and use cases

- present weasl to you using customer examples

- take a look at the live system together.

Feel invited to make an appointment with us.