Objectives for manual assembly in production: more process reliability, fewer errors

Despite advancing digitalization, many assembly processes in production remain characterized by manual work steps. Particularly in the case of more complex products, assembly and final assembly often take place manually.

In order to avoid costs due to rework in production or later due to customer complaints, error reduction in manual assembly is one of the top priorities.

The most important course of action for achieving this objective is error prevention, i.e. errors are not made in the first place. However, since people are human and therefore not infallible, error detection is just equally important in order to uncover errors that have been made at an early stage and, if possible, directly during assembly.

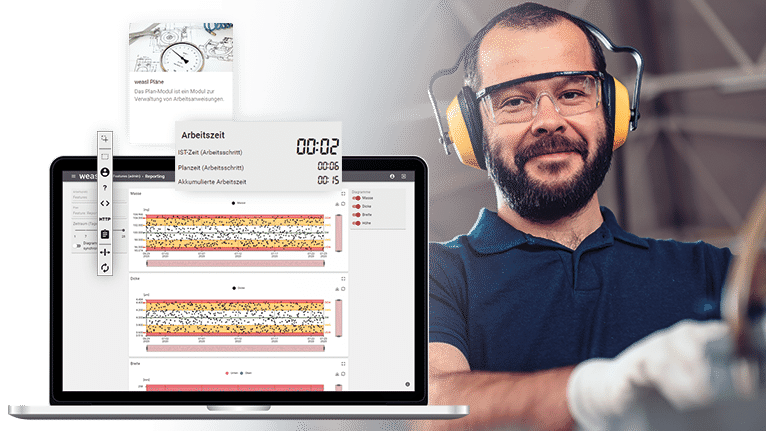

In these regards, our worker and assembly guidance system weasl offers optimal support in terms of content guidance and process-related management of workers in the execution of their manual assembly and testing steps.

Error prevention and error detection - the path to an optimal assembly process

What causes assembly errors?

The causes of assembly errors include, for example, unclear and misleading work instructions, incomplete or outdated assembly information and also the occasional carelessness or distraction of the workers themselves.

Forgotten work steps, mixed-up or incorrectly assembled components, and unrecognized errors lead to increased costs and reduced sales.

How can you prevent assembly errors?

It's very simple! Among other things, provide the worker with unambiguous work instructions, make the required information available up-to-date and directly at the workplace, and detect errors - e.g. due to carelessness - preferably directly during assembly.

With our worker and assembly guidance system weasl, all these points can be implemented without any problems.

How can a guidance system like weasl support the assembly process?

Detailed assembly instructions and a precisely specified assembly process combined with explicit, if necessary process-locking test steps at critical points give the worker security in the execution of his manual work steps and at the same time lead to more control and thus a sensitization of the employees.

At the same time, and almost as a "side effect", the use of worker guidance enables you to achieve a continuous digital assembly process without media discontinuities in the transfer of information, as well as automatic documentation of all production steps.

weasl – for the optimization of your assembly processes

Always up-to-date work instructions for error-free and flexible assembly: With our worker and assembly guidance system weasl, you have access to a powerful tool that supports you in optimizing your manual assembly.

We invite you to attend our worker guidance webinar

Learn how to master typical challenges in manual production with a worker guidance system. Using real-life examples, we will show you what modern systems can do and how you can directly benefit from them.

E-Paper: How do you find the right system?

What do worker guidance systems do and where can you use them successfully in your company? We show you the key points to watch out for and how to find the right worker and assembly guidance system for your company.