With weasl you are in good company

"weasl is our control system in the assembly line and we can integrate our CIP process perfectly into the 'doing'."

Christian Sperka

Master Metalworker (HWK) | Welding Specialist | Order Coordinator | Responsible Welding Supervisor

"With a growing shortage of experienced and qualified employees, weasl is the lever to ensure assembly quality."

Elmar Reuter

Retired Managing Director

"In iSAX, we have found a partner who can flexibly integrate our products into customer applications and implement our requirements in a solution-oriented manner. This makes us a good team for mastering the future requirements of smart production."

Lars Grupe

Manager Industrial Engineering

"The longer we work with weasl, the more interesting the product becomes within the company. We want to expand weasl further and develop it into a permanent fixture in our day-to-day production."

André Hink

Head of Prototype Shop and Production

"With weasl, iSAX has created a worker guidance system that is not only state of the art, but also appealing and easy to use. The excellent support and continuous further development are fantastic."

User rating

at Capterra

"With weasl, all options for designing efficient digital worker guidance are available, in addition to plant management itself, as well as comprehensive work plan creation and functions for order scheduling."

Conclusion of the

Factory Innovation product review

Read review

Start small, scale flexibly with weasl

Start small

You can fully integrate weasl into your IT and OT and map the most complex processes. But you don't have to. Start small and use weasl as a stand-alone solution - on-premises or in the cloud. Become productive with weasl immediately.

Work fast

Use what is already there: Your existing instructions and documents. Import images, videos, PDFs etc. into weasl and create your first checklists and work plans in just a few clicks.

Scale flexibly

Scale up when you are ready. And then exactly as you need it. Interlocking with your IT and OT? Sure. Increasing the complexity and dynamism of your digital instructions? No problem. Rollout to other production areas? Flexibly realizable with weasl.

What is weasl and what are the system's key features?

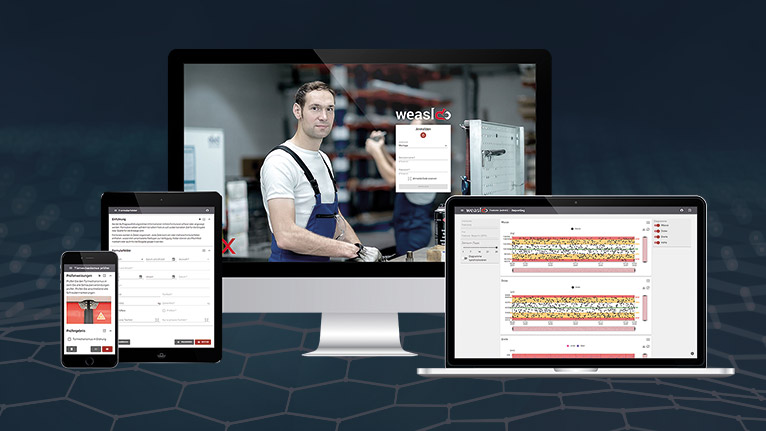

Our worker guidance system weasl is the optimal solution for more efficiency in your production. It adapts to the skill level of your workers and guides them individually and safely through the work instructions in a wide variety of work plan variants. This puts you a decisive step ahead of the competition.

We have developed weasl so that you can support and relieve your workers in their manual activities in assembly and production. Watch our feature video to find out which functions weasl offers and what benefits you can gain from it.

Get video access

![]()

SaaS & On-premises

![]()

Integrated into your IT / OT

![]()

Modularly expandable

![]()

Encrypted & secure

![]()

Mobile & stationary

![]()

Subscription software

How can weasl benefit your company?

Processes in manual assembly require a lot of knowledge, preparation and skills from the employee. With our worker guidance system weasl you create an important interface between the planning and execution of work orders, between information / systems and your workers.

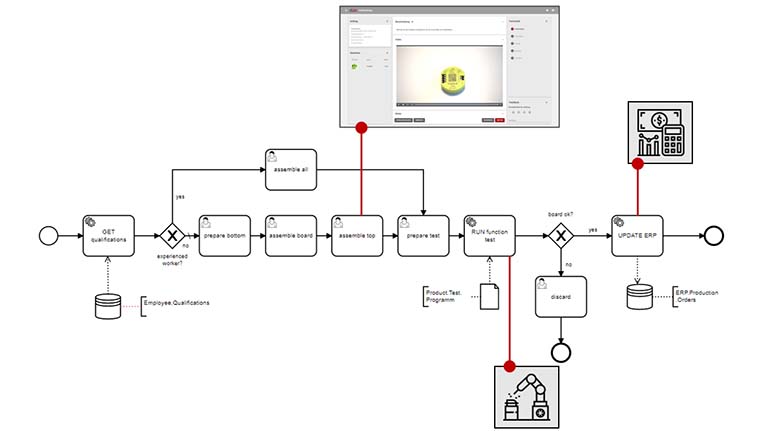

Display complex work plans in a simple way

- manual or automated modeling of processes

- creating work instructions – from simple checklists to complex decision trees

- mapping and linking manual and automated work steps

- integration of external media and third-party systems

Product info Take the Quick Check

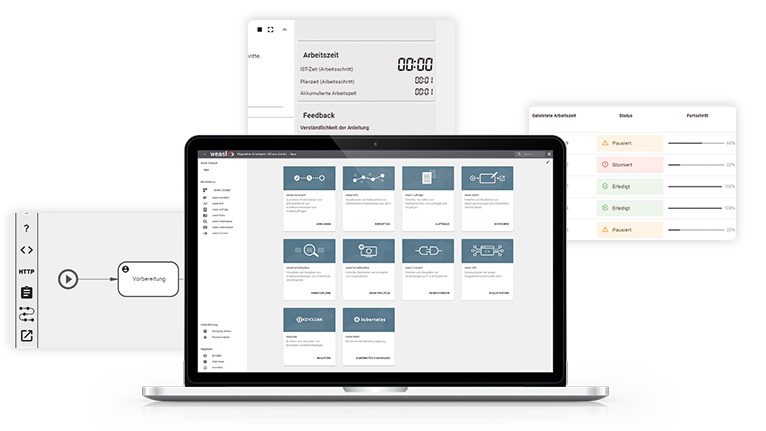

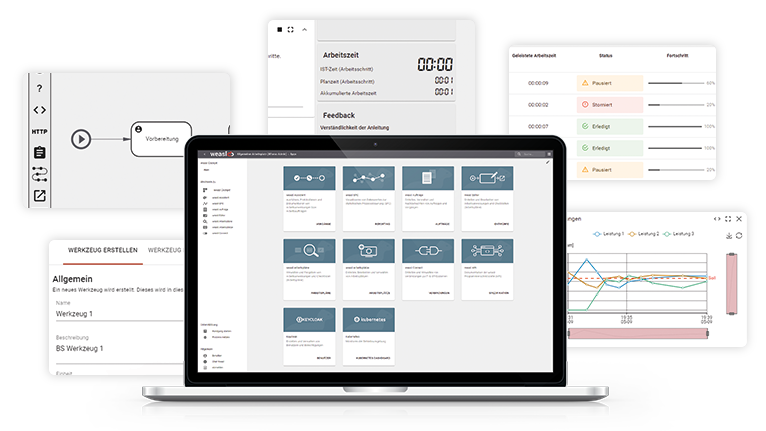

Which core functions does weasl offer?

At the center of weasl is the work order, which must be mapped, processed and documented. Therefore, our system provides you with all the tools you need to create or import your work plans, to make them available to your workers digitally and precisely to the order, and to document all work progress in a verifiable manner.

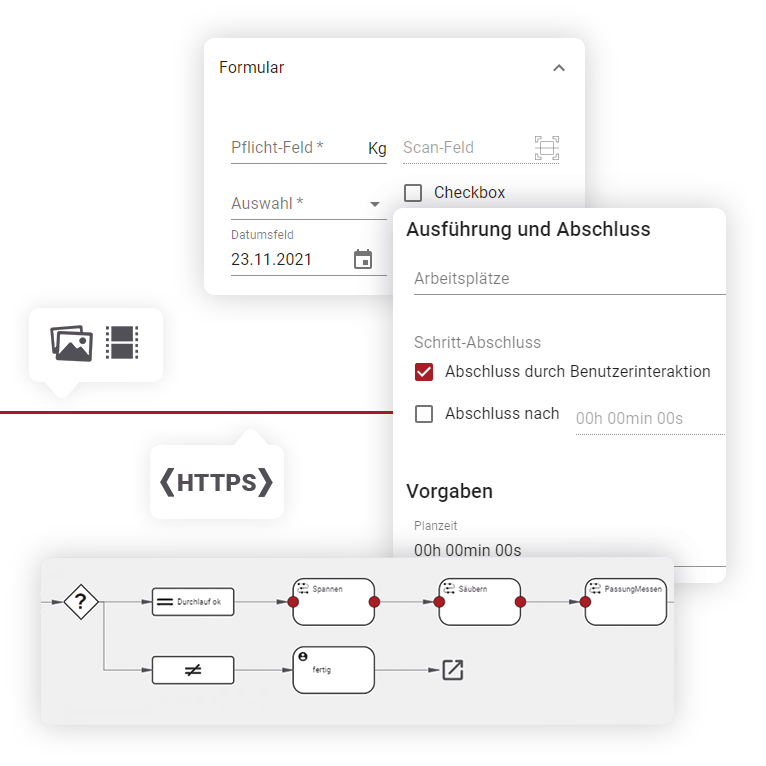

For authors of work instructions:

Work plan editing

Use the editor to easily create, edit and manage work plans or generate them automatically.

- model processes

- create work steps

- integrate documents

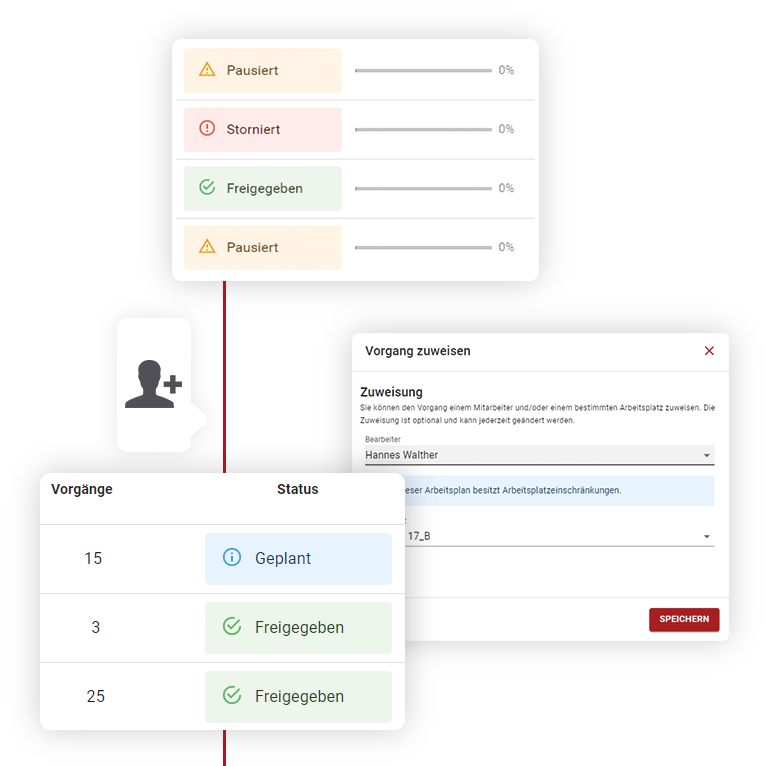

For dispatchers and foremen:

Order management

With weasl you manage the distribution of orders to be processed to workstations and available workers.

- import/create orders

- manage orders

- review orders

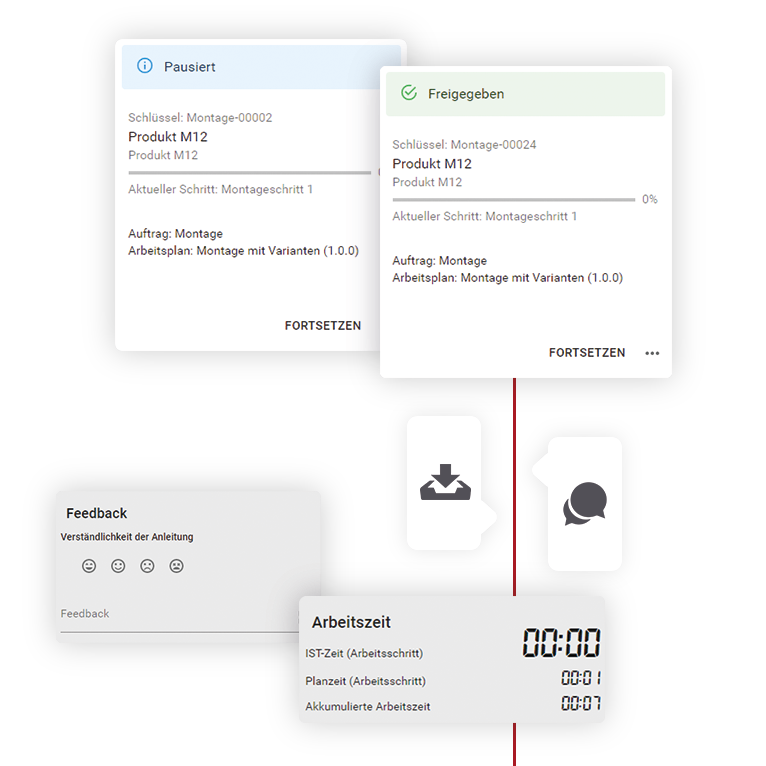

For workers:

Order execution

Our guidance system leads your workers through their orders and logs all progress and entries.

- carry out assembly steps

- carry out test steps

- document results

weasl packages to fit your needs

weasl flex

Flexible creation, processing and documentation of work plans and checklists

weasl max

The functional scope of weasl flex combined with maximum integrability.

Securely integrated on leading platforms

With weasl, you decide how best to integrate the system into your existing environment. We recommend operation as software-as-a-service and AWS as the cloud platform. Other cloud platforms such as MS Azure are also possible. We offer weasl as an app in the ADAMOS STORE or as an app on the MPDV Manufacturing Integration Platform (MIP). In addition, numerous other integration options are open to you thanks to compatibility with TRANSCONNECT. This means that some of the most important industry platforms are available to you as a basis for weasl and numerous other IoT projects.

Read more about application areas & functions

Use cases

weasl is highly customizable and adapts exactly to your conditions and processes. At its core, it is always the ideal guidance system for use cases such as:

- worker guidance

- quality control

- tracking & Tracing

Application areas

Our system guides you safely through the processes along your value chain. It provides digital work instructions and checklists for, among other things:

- production engineering

- assembly

- maintenance

Benefits & advantages

Make the right adjustments to leverage unused potential:

- reduce training times for your employees

- reduce media discontinuity by means of consistent digitally designed work plans

- ensure product quality through digital quality control

Feature overview

With weasl, all essential features for the optimization and digitalization of manual processes are at your finger tips.

- graphical drag & drop editor

- integration of drawings, videos, ...

- documentation, reports, quality control