Customer benefits at a glance

< 50%

time required to create an assembly order

-100 %

manual creation of packing lists and parts lists

-50%

time required for work preparation

-100%

documentation

efforts

-30%

costs for external complaints

Our customer & his initial state

Alpha Verteilertechnik GmbH

Industry: metal treatment & control cabinet construction

Company headquarters: Cham, Bavaria

Employees: approx. 230

Founded: 2004

Alpha Verteilertechnik specializes in the production of standardized insulation and power distribution cabinets as well as customized control cabinets. The production of Alpha 3200 power distribution cabinets (assembly and quality assurance) was to be digitalized through the use of a worker guidance system.

The Alpha 3200 CLASSIC and Alpha 3200 ECO power distribution cabinets consist of a combination of more than 4,000 possible assemblies, which in turn are made up of more than 30,000 different individual parts. Each customer order / power distribution cabinet is individual - i.e. batch size 1. Details like the specific mounting position of parts result from certain electrical parameters, dimensions of the enclosure, or cross-sections of copper rails. Depending on the screw diameters and application, defined torques must be used by the fitters.

„With a growing shortage of experienced and qualified employees, weasl is the lever to ensure assembly quality.“

„With a growing shortage of experienced and qualified employees, weasl is the lever to ensure assembly quality.“

Elmar Reuter | Retired Managing Director | Alpha Verteilertechnik GmbH

Challenges & motivation for the use of a worker guidance system

Mastering

complexity

Order scheduling: The customized configuration of the control cabinets requires a lot of time-consuming manual work in order scheduling (e.g. with Excel) in order to prepare the individual parts lists and assembly information.

Assembly: The large number of possible assemblies in conjunction with batch size 1 requires the fitters to work intensively with the parts lists, the drawings and the underlying electrical and mechanical values. This is estimated to take up to 20% of the total assembly effort.

Facing the

shortage of skilled workers

The rapidly increasing number of customers leads to an ever-increasing number of cabinets to be manufactured. This requires more skilled workers, efficient assembly work and precise assembly instructions, especially for less qualified specialists.

Securing

quality

Quality defects that are only discovered when the cabinets are in use at the customer can lead to considerable cost risks. Possible rework can also only be carried out during regular maintenance appointments, as this is the only time the cabinets are taken off the network.

In view of the growing shortage of skilled workers and the expected increase in volumes, Alpha Verteilertechnik has identified an increased risk of quality defects and thus potential additional costs and efforts.

Task & solution description

Order scheduling

Task

Development of a guidance system that automatically creates customized assembly instructions for the fitters, including the required parts list information, during order scheduling for customer-specific control cabinet configurations (batch size 1)

Implementation

- implementation of order management for the creation of assembly orders, their assignment to fitters/workstations, for an overview of the order status and order review

- automated generation of step-by-step assembly and inspection instructions

- calculation of an order parts list for ERP import and order-specific packing lists

Assembly

Task

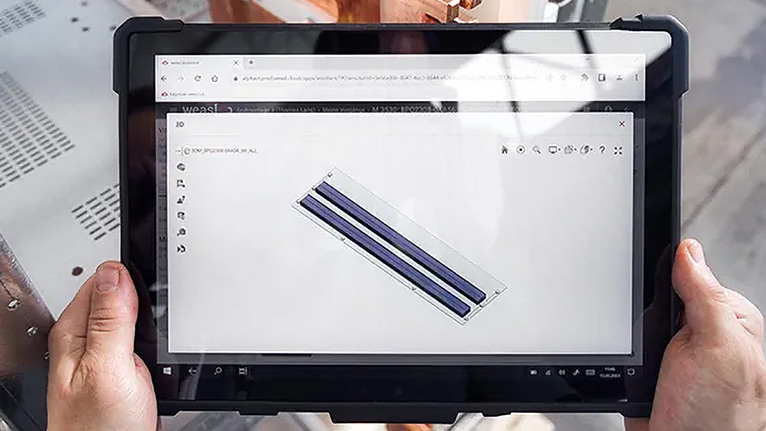

Development of an guidance system that guides the fitter through the assembly process in a structured manner with a defined sequence, parts list information, images and drawings as well as supplementary assembly information (torque, quality instructions).

Realization

- execution of assembly orders including worker self-inspection, customizable quality control and dynamic assignment of rework

- creation of different test reports (both for each individual enclosure field and across all systems)

- creation of printable step-by-step assembly instructions for each order as an emergency backup in the event of a system failure

Goals

Reducing cost risk by avoiding errors & ensuring quality

Cost reduction through shorter production times

Creating the basis for managing higher production numbers during a growing shortage of skilled workers

Side effect: cost reduction through shorter order scheduling times

Benefits of weasl for order scheduling

- The time required to create an assembly order has been reduced to less than 50% - from 10 to approx. 5 minutes. Time saving: approx. 5 minutes per order

- The manual processing and creation of packing lists and order parts lists has been completely eliminated. Time saving: approx. 17.5 minutes per order

Benefits of weasl for assembly

- Work preparation times (gathering information) have been significantly reduced.

- The documentation effort is reduced by 100% – no more paper, quality assurance is recorded digitally directly during assembly/final inspection. Manual logs are no longer necessary and the follow-up of complaints is significantly simplified.

- The error rate is significantly reduced. This reduces the costs for external complaints by up to 30%.

- A basis is now in place to handle more orders in a quality-oriented manner in the face of an increasing shortage of skilled workers.

The solution behind the success of Alpha Verteilertechnik

A worker guidance system can give your company a noticeable boost. The prerequisite for this is software that is flexible enough to adapt ideally to your needs. Alpha Verteilertechnik has found just such a solution in our weasl system.

Because weasl can:

- map processes as they really are – as linear sequences or as complex process paths and decision trees.

- provide all relevant media – whether images, text, Excel, CAD or forms.

- communicate with your existing systems thanks to open interfaces.

- be flexibly expanded – with additional modules or customized, individual apps.

- be tailored precisely to your operating model – be it a SaaS environment or your own server.

- be used in different application areas – from order scheduling and assembly to quality assurance or the maintenance of your machines and systems.