Definition: What is a zero-defect strategy?

The zero-defect strategy - or alternatively zero-defect management or zero-defect principle - is a concept in quality management and within continuous improvement processes (CIP) that follows the basic idea: The only acceptable error rate is the zero error rate. This means that there must be neither rejects nor rework.

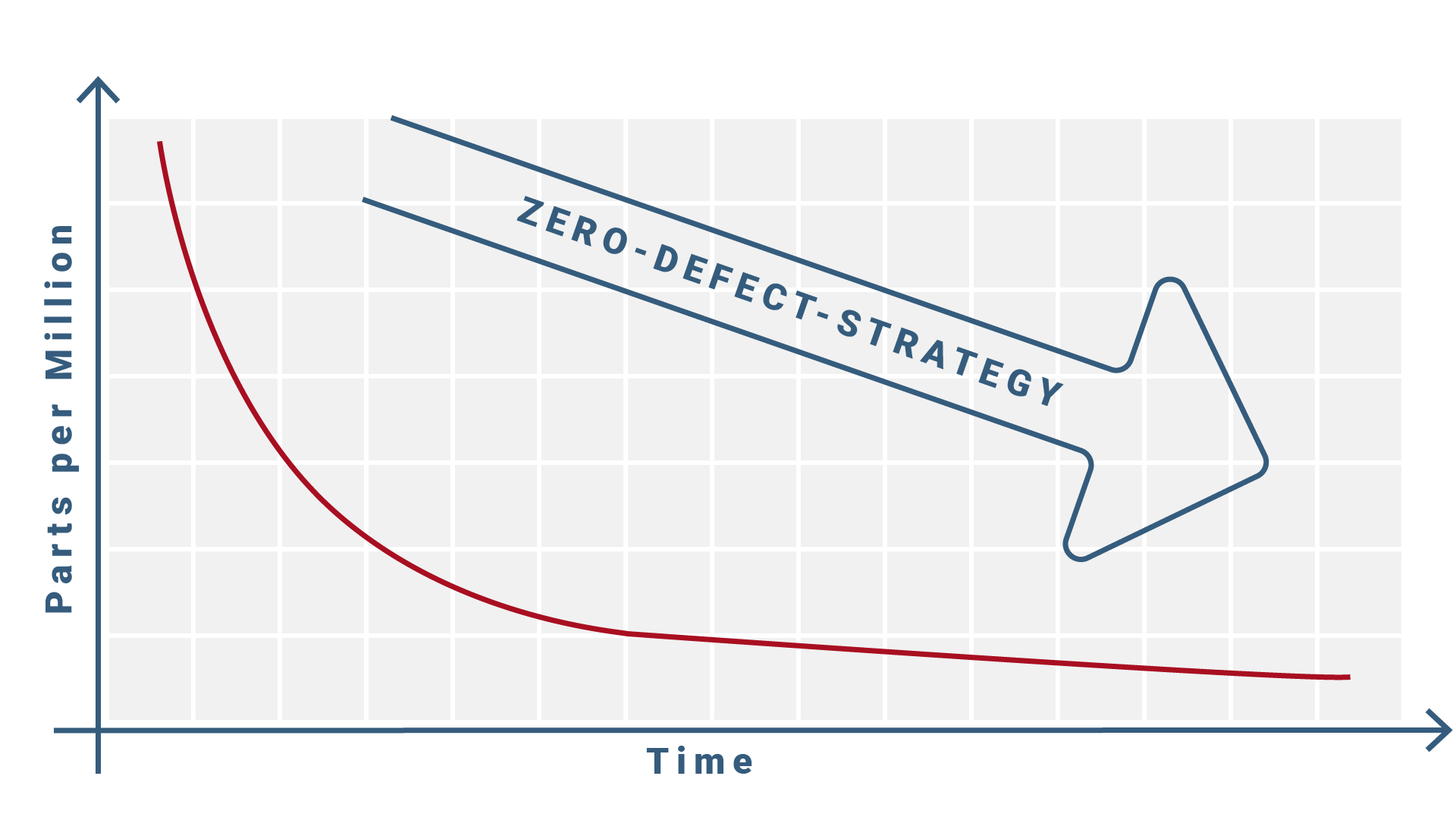

However, this already shows that it is rather unrealistic to implement such a strategy consistently. It is more realistic to approach zero defects using the value “defects per million possibilities” or ppm for short. The target is 10 to 20 ppm, i.e. 10 to 20 errors per million possibilities.

The zero-defect strategy was developed by one of the great pioneers of quality management, Philip B. Crosby. Crosby asked himself: “Why should companies waste a lot of time and money detecting, defining and combating errors when it is possible to prevent them from occurring in the first place?” The result of his analyses and evaluations was, among other things, the zero-defect strategy.

What are the prerequisites for a zero-defect strategy?

In order to achieve zero defects, you must of course first find out where the sources of defects lie - and eliminate these sources sustainably.

Are these errors in your raw materials? Then switch to better suppliers and ensure that you only use tested, high-quality materials.

Are these errors in your machines? Then make sure that your machines always run smoothly and are maintained accordingly - preferably with predictive maintenance.

Do these errors lie with your employees? Then qualify them further through regular training and courses. In addition, create quality awareness among your employees and promote it continuously. Involve your colleagues in the quality assurance and improvement processes.

How do you implement a zero-defect strategy?

A zero-defect strategy must be supported by the entire company. Therefore, first of all, you need the full commitment of the management level.

Next, you need absolute transparency. Your goals must be just as crystal clear as the path to achieving them. Define in detail what is to be achieved, by what means and to what extent. And also what counts as a failure.

A zero-defect strategy also requires an active quality culture, which you must establish company-wide or at least in the department concerned.

To ensure that all of this works, you should get support on board: from your colleagues and from relevant tools and concepts. Do you already have a quality management system? Are you already exploiting the benefits of a worker guidance system for error-free work? Have you ever thought about concepts such as Poka Yoke?

Now that you have established new tools and processes, you need to maintain a high level of understanding and acceptance among your employees. Train your workers regularly and involve them wherever possible.

And once everything is established, it's time to evaluate and optimize in the sense of a continuous improvement process. There is little chance that your zero-defect strategy will be perfect the first time around, or that it will achieve 10 to 20 ppm. Collect data, evaluate it and optimize it.

Advantages of the zero-defect strategy

Are you familiar with the Rule of Ten? It states that the later an error is discovered in the value chain from planning to the customer, the higher the cost of rectifying the error. At each stage, the costs are multiplied by 10.

This clearly shows why a zero-error strategy is such a valuable approach: even if you will never really arrive at zero errors, every error that is not made may save you immense costs.

The initial outlay for a zero-error strategy may seem huge, but avoiding errors is always cheaper than correcting them. Not to mention: reducing production errors increases customer satisfaction and your reputation as a manufacturing company.

And because you have always involved your employees on the way to zero defects, you have also strengthened their loyalty to you and your processes.

The key to zero defects in manual work

Unfortunately, we cannot provide you with a solution for high-quality materials. But we can ensure that your employees master their work orders flawlessly - regardless of their skill level.

All you need is our weasl worker guidance system. Experience it for yourself - in our free showcase environment.