Definition: What are process instructions?

The process instruction is used for the structured documentation of the sequence of activities and procedures within a process. It is therefore an important documentation tool for quality management and can even formalize cross-workplace regulations for the implementation of standards.

This is relevant, for example, if you carry out certifications such as ISO 9000, as these require “documented procedures” that include process descriptions and work instructions in addition to process instructions.

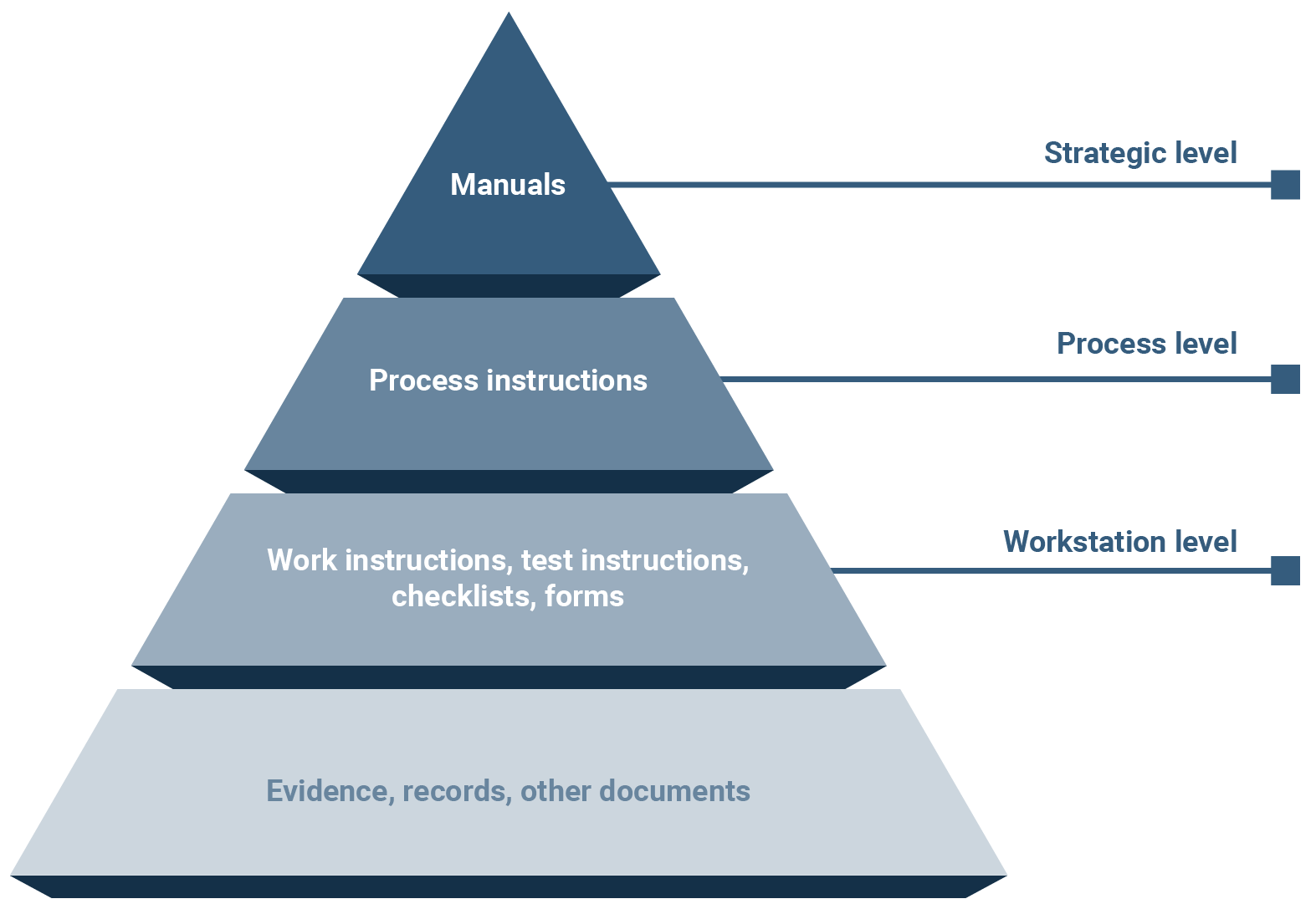

Process instructions tend to contain overarching and more general information on procedures. Work instructions, operating instructions etc. are responsible for more specific instructions.

How do you set up a process instruction?

If you want to create a process instruction, you should work through the following steps in sequence:

Step 1: Define the target group. Who is affected by the process instruction? Who should work with it?

Step 2: Document your processes and structure them logically. You determine the sequence of your procedures.

Step 3: Draft a template for your process instructions that you can also reuse in the future. Be sure to use clear and consistent wording in the documentation. Our tip: It is best to use a digital system.

Step 4: Involve your employees now at the latest - or even earlier if you prefer - in order to clarify any questions of understanding and create an awareness of the resulting processes.

Step 5: Once the first draft of your process instructions is ready, carry out test runs. Does everything fit or do you still need to make adjustments?

Step 6: Train your employees on the new process instructions - both when introducing new ones and when updating them.

Step 7: After the process instructions is before them. Keep a constant eye on your process instructions and check them regularly for potential updates.

What are the advantages of a process instruction?

We have already referred to standards above and, in fact, the process instruction is an important tool for ensuring compliance with standards (e.g. DIN EN ISO 9001, DIN EN ISO 14001, DIN ISO 45001:2023).

Furthermore, process instructions are not limited to individual persons. Rather, they standardize procedures across teams and locations.

Process instructions ensure compliance with regulations and enable effective auditability. They also increase process reliability in your company.

What content should be included in a process instruction?

In order for a pocess instruction to be useful, it must contain a basic set of information. This includes

- the purpose: Why does the process instruction exist? What is the objective?

- the area of application: Where and when is the process instruction applied? Which departments, processes and locations are affected?

- supplementary documents: What additional documents are there? Are there, for example, work instructions, safety guidelines, operating instructions or process diagrams that are related to the process instruction?

- the topic: What is the content and focus of the process instruction?

- a change history: When and why were changes made to the process instruction?

Examples of process instructions

Process instructions are always used when a general procedure is to be described in a specific situation. The aim here is not to go into operational detail. Process instructions are therefore used in the following situations, for example:

Measures in the event of an incident

In this case, the process instructions clarify

- how you or your employees should behave in the event of an incident.

- how you react in the event of an unexpected machine failure.

- how a quick fault diagnosis can be carried out.

- who should be notified.

- how further coordination is carried out.

Details on specific implementation can be found in the more detailed instructions, such as the operating instructions (e.g. in the event of a machine failure) or the digital work instructions (e.g. for fault diagnosis).

Customer service

Process instructions also provide valuable support in customer service. They clarify:

- How are customer inquiries documented and prioritized?

- How are employees assigned to customer inquiries?

- How can the customer's problem be resolved, documented and subsequently invoiced?

Process instruction vs. SOP vs. process description

Let's take a look at how the process instruction differs from other concepts.

Process instruction

What is it?

The process instruction is used to document procedures and their implementation specifications. It also contains additional documents that are required for the implementation of activities.

For whom?

Heads of department and employees

Standard operating procedure (SOP)

What are they?

Standard operating procedures are very detailed step-by-step instructions for carrying out tasks. Even though SOPs are much more practical than process instructions, they are often used as a synonym.

For whom?

Operational employees

Process description

What is a process description?

A process description is the general description of the flow of processes, including interfaces to other processes, input and output.

Who is it for?

Process owners and management level

Supplement your process instructions with SOPs from weasl

Your employees in production need to know how to proceed in certain situations. What they need above all, however, are detailed instructions that guide them step by step through the processes.

Whether operating instructions or digital work instructions - with weasl you can easily implement your SOPs. Experience it for yourself - in our showcase environment.