Definition: What is process data collection (PDC)?

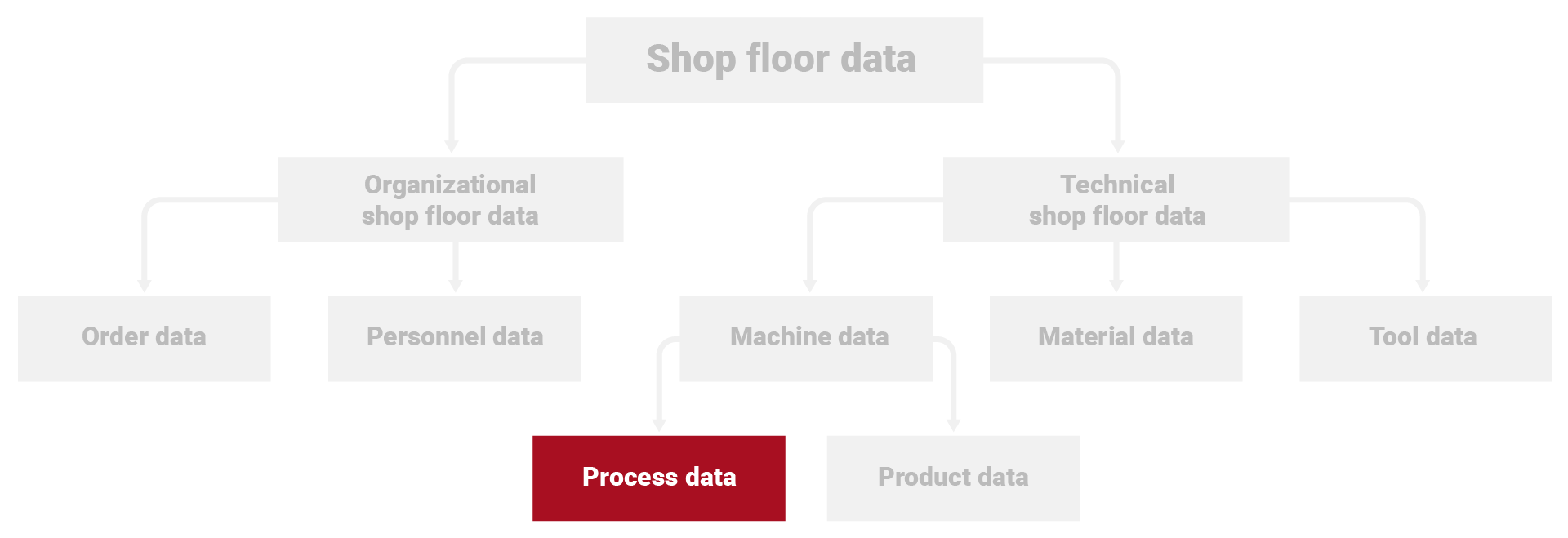

Process data collection - alternatively also known as process control or process monitoring - is the systematic recording of all data that provides insight into the course of production processes. Process data collection is a component of shop floor data collection and as such is classified under technical production data. Alongside product data collection, it belongs to the complex of machine data collection.

The process data itself can be further subdivided into

- quantitative process data: measurable data such as temperature and energy consumption

- qualitative process data: Contextual information such as order number and shift data

What are the benefits of process data collection?

As with any type of data collection, process data collection also creates transparency in your production - in this case in relation to the processes.

The prerequisite for being able to benefit from your process data is not only the collection but also the appropriate preparation and further processing of the process data. Once this has been mastered, the process data enables

- rapid detection of quality deviations

- the identification of optimization potential

- the real-time monitoring of production processes

- fulfill regulatory requirements (compliance and traceability)

- support the monitoring of and compliance with targets

How to implement process data collection (PDC) in your company

No matter what you want to implement in your company: It won't work without the right strategy. That's why you also need to start developing a viable strategy on the road to process data collection:

- Define your goals.

- Determine which process data is relevant and should be recorded.

- Also think about the details of data collection. Which data should be collected and how often?

- Which data should be collected continuously (e.g. pressure and temperature), randomly (e.g. material flow) or on demand (e.g. faults)?

Once the strategy is in place, the search for a specific solution can continue. Check which software and hardware is required to achieve the set goals. Test your favorites before making a decision. And evaluate whether you want to record process data manually (e.g. using checklists or forms by employees), automatically (e.g. using controllers and sensors) or using a combination of both methods.

Once the right solution has been found and introduced in the company, the actual process data collection can begin. At the same time, you should train your employees and explain to them what needs to be done for correct data collection.

Once you have collected sufficient data, the next step is to analyze the process data in order to gain more transparency about processes and make data-based decisions. Incidentally: The collected process data can be converted into process KPIs and thus compared over a longer period of time. This is particularly important for certifications such as DIN EN ISO 9001.

Finally, you should always put your process data collection to the test. Monitor and optimize the established processes and increase their efficiency.

What are the goals of process data collection?

The primary goal of process data collection is, of course, to make processes more transparent on the basis of data. Only if you have an insight into the data behind the processes can you make sustainable decisions.

On the basis of collected process data, it is possible to consistently monitor and control production processes, allowing you to detect and rectify errors and problem areas promptly.

This in turn is a fundamental milestone on the way to sustainable production optimization.

The easy way towards manual process data collection

A lot of process data is generated while your employees are doing their work. So why shouldn't you record this data in the same breath? It's easy and doesn't involve any significant additional work for your employees - with our worker guidance system weasl.

Experience it for yourself - in our free showcase environment.