What is machine data collection (MDC)?

Machine data collection - or MDC for short - refers to the collection of all data generated by a machine during production. This data can be collected, for example, via sensors attached to the machine, a PLC or an MDC or PDC terminal.

Machine data collection is also referred to as machine monitoring or machine condition monitoring.

Establishing machine data collection, but how?

If we look at the word alone, we might come to the conclusion: The data just needs to be captured, then it's fine. But MDC projects involve much more than just establishing connectivity for data collection.

Step 1 is, of course, connectivity - insofar as the machines are not yet able to speak. The aim is to enable access to data using sensor technology, for example.

Step 2 is data processing. Up to this point, some data has been stored somewhere in some format. Now this data needs to be made usable.

Step 3 deals with data storage - centrally and accessible to everyone. The processed data is saved for the long term and made accessible for further use.

Last but not least, step 4 is data utilization. Here, the data is translated so that it can serve as a basis for decisions. Common methods include user- or purpose-specific evaluations or dashboard applications.

What are the advantages of machine data collection?

The data from your machines opens up countless opportunities for process optimization.

If you know what makes your machines tick, you will also understand when they are reaching their limits. Accordingly, you can use machine data collection to optimize your machine running times and plan maintenance processes better. In the best case scenario, downtimes can be minimized and productive times maximized. You can even derive data-based measures to optimize machine utilization from downtimes.

If sensors or your employees report a fault via a terminal, you can react immediately and also use the reported data later to analyze optimization potential.

MDC: What machine data is available?

In the case of machine data, a further distinction is made between process data and product data.

Process data is all data that is required for operation or is generated during operation. This can include power consumption or pressure, for example. The aim of collecting this data is to monitor production processes - not the product itself, but the process around it.

In contrast, product data is directly related to the product - for example, quantity, dimensions or weight. You record product data in order to analyze production quality.

Other examples of data that you can collect in the course of machine data collection are

- the production quantity

- the number of parts

- the number of rejects

- capacity utilization

- production times

- the availabilities

- the machine status

- energy consumption

- downtimes

- set-up times

- the reasons for malfunctions

Isn't machine data collection (MDC) the same as shop floor data collection?

Short answer: No. Even though machine data collection (MDC) is often compared to shop floor data collection, there are different areas of data collection behind it.

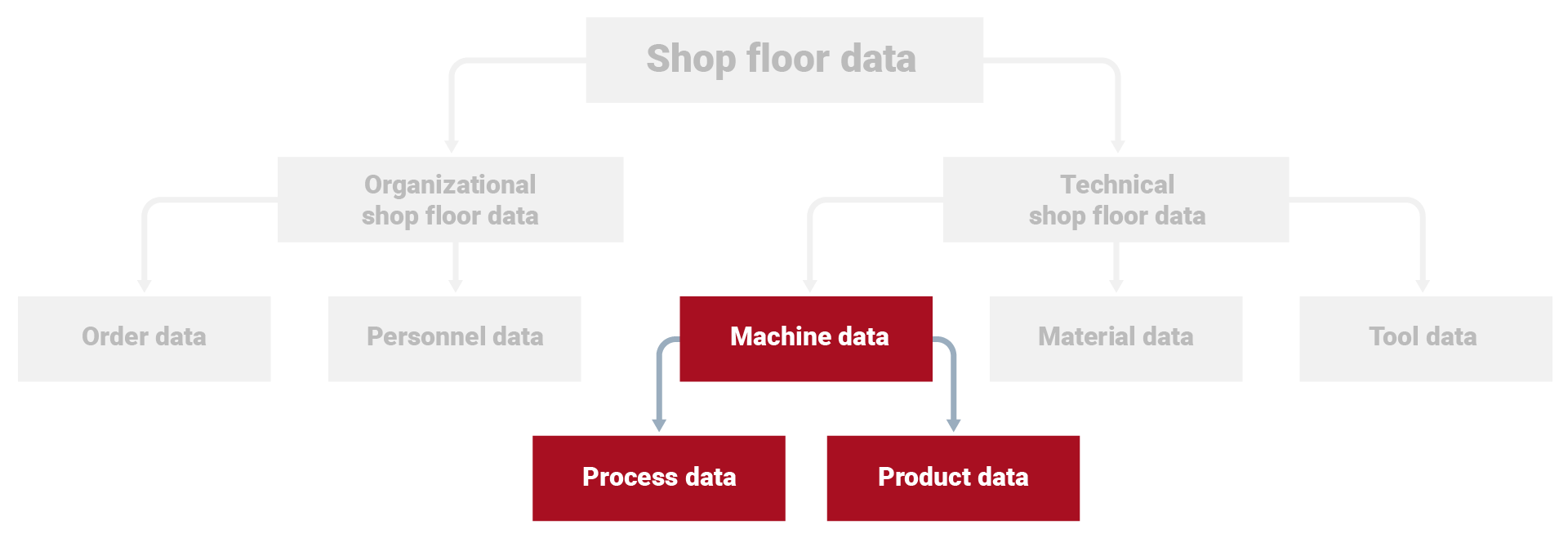

Store floor data collection includes both technical and organizational data that can occur in a company. And technical operating data in turn includes material data, tool data and machine data.

Machine data collection is therefore part of technical shop floor data collection.

What are the goals of machine data collection?

As with all data collection, the primary aim of machine data collection is to create transparency. Consistently recorded and comprehensibly prepared machine data provides insights into past and current machine statuses and makes forecasts possible.

In this way, machine data collection ultimately serves to monitor, control, analyze and optimize production.

The easy way towards basic machine data

Do you want to establish machine data acquisition in your company? Then there is usually no way around complex IIoT updates in the form of sensor technology and data analytics. But simpler scenarios can also be implemented with our weasl worker guidance system. After all, your workers already record machine data during processing.

You can see what this can look like in our free showcase environment.