What does First Time Right mean?

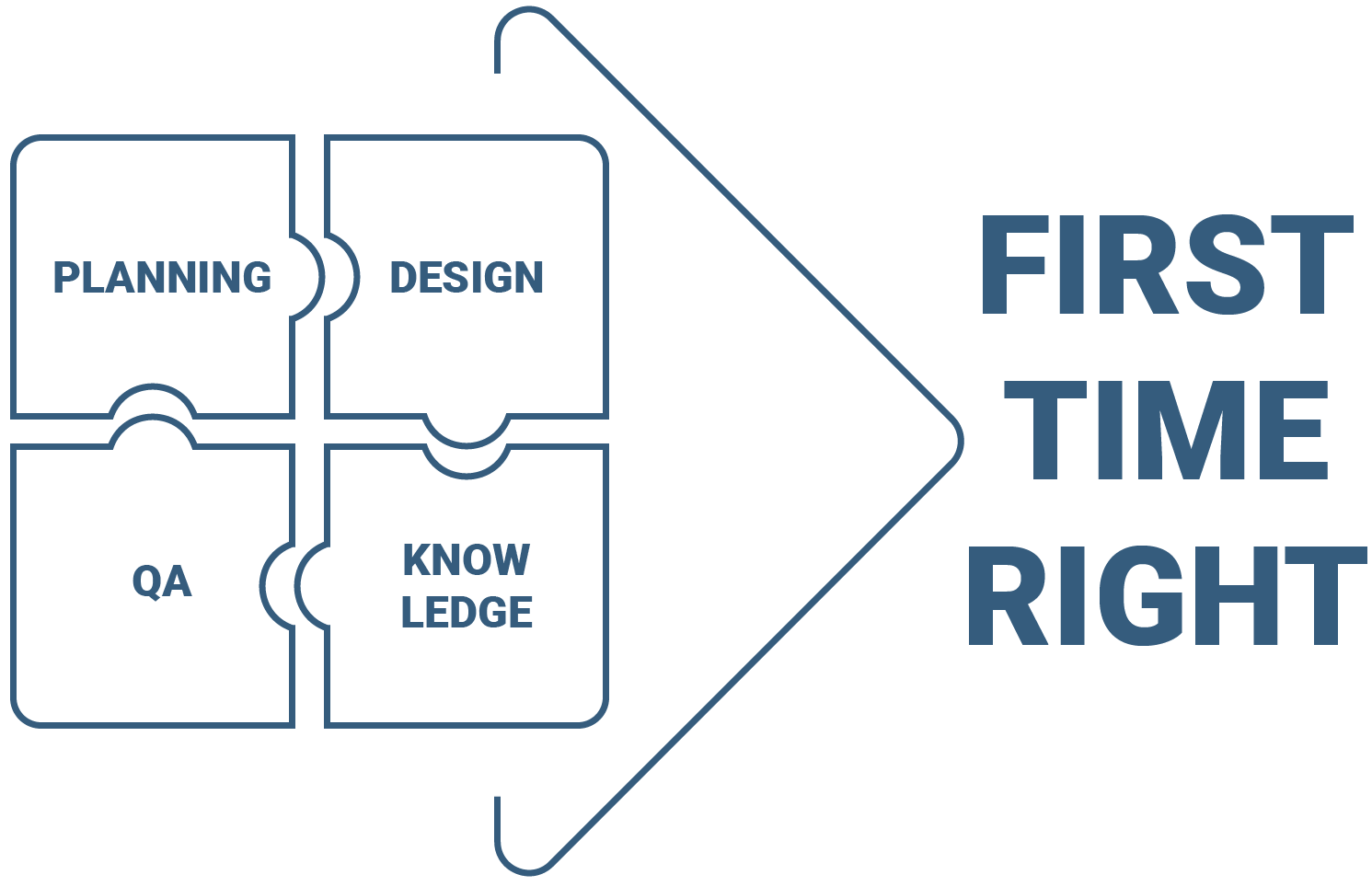

First Time Right (FTR) - or alternatively Right First Time - is a concept from Total Quality Management. It aims to carry out processes, tasks or activities without errors or rework right from the start.

The aim behind this is to increase efficiency and save time and costs by achieving the highest quality from the very first run.

First Time Right can refer to manufacturing and production as well as to data quality and software development. The latter is not of interest for this article.

How does First Time Right work and what needs to be guaranteed?

In order for a product to be manufactured correctly on the first run, the prerequisites must be clear and all possible stumbling blocks along the way must be eliminated.

This requires thorough planning and should be supported by implementation-focused quality assurance measures such as design for assembly. However, the execution itself must also follow clear rules and be guided along precisely defined paths.

Throughout production, quality assurance and quality control measures should be established at various and particularly critical process steps. And, of course, you need a clear definition of when a product is OK or not OK.

The icing on the cake is the monitoring of the processes themselves. Optimize your processes continuously in order to be prepared for all eventualities.

What are the advantages of First Time Right?

Before we talk about the advantages: If you take a look at how it works, you will have noticed that First Time Right is not something you can just shake out of your sleeve. It takes time, a lot of insight and watertight processes. We could indeed initially see this as a disadvantage. But there are also numerous advantages. These include

- greater efficiency thanks to error-free processes

- elimination of rework

- significant time savings in production and assembly

- saving of resources

- reduction of costs with simultaneous increase in quality

- higher customer satisfaction

Sample calculation

First Time Right (FTR) is not only at home as a concept in quality management, but also as an important key performance indicator (KPI). With the FTR KPI, you can measure how many products were manufactured correctly on the first run and how these relate to the total number of products produced.

This results in a percentage that creates transparency about the efficiency of your production. The higher the percentage, the higher the efficiency. An example:

You have produced 100 machines. Of these, 89 machines are without defects according to your definition. 11 machines have to be reworked.

89/100 = 89 percent. Your FTR is therefore 89%.

The ideal tool for an optimal first-time-right ratio

When it comes to producing without errors and rework, there is no way around optimal guidance for your employees in assembly and production.

With our worker guidance system weasl, you provide your workers with a powerful tool that guides them to a flawlessly manufactured product in line with qualifications and processes. See for yourself - in our free showcase environment.