Definition: What is a bill of materials (BOM)?

A bill of materials (BOM) is a detailed list of all the materials, components and parts required to manufacture a product. It contains information on the quantity and arrangement of the components and serves as the basis for production planning and control.

A basic distinction is made between eBOM and mBOM.

Two types of bill of materials: eBOM vs. mBOM

eBOM – the engineering bill of materials

The eBOM – or engineering bill of materials – is a bill of materials that contains all the technical details and elements used in the design phase of a product.

This includes, for example

- precise specifications

- design drawings

- technical documents

mBOM – the manufacturing bill of materials

The mBOM – or manufacturing bill of materials – is used in manufacturing practice, i.e. when it comes to actually manufacturing the designed product.

Accordingly, the manufacturing bill of materials (mBOM) includes all materials and individual parts, including the quantities required to manufacture the product.

Differentiation of bills of materials according to variance

An alternative method of differentiating bills of materials is derived from the variance of the product to be manufactured. If you manufacture products with identical features and specifications, you use a standard BOM for this.

If, on the other hand, you manufacture products with many variants and have to produce a product in different colors, for example, then you also have to use different BOMs. You can cover this with configurable bills of materials.

Advantages of a bill of materials

Of course, the advantages vary depending on the type of bill of materials. An EBOM is probably of little use to your workers and an MBOM is out of place in product design. But each type of bill of materials has clear advantages.

An EBOM, for example, helps your engineers to create accurate and comprehensive product designs.

An MBOM is invaluable in production: it ensures that all required parts, materials, tools, etc. are available for production or that there is transparency about which components always belong to a particular product.

Speaking of transparency: a BOM also creates transparency across the board - namely regarding the required materials and the associated costs. This is of central importance for material requirements planning at the latest.

A bill of materials bundles components, assemblies and characteristics per product. This in turn enables the central management and analysis of product data and ultimately the optimization of production processes.

Structure of a bill of materials (BOM)

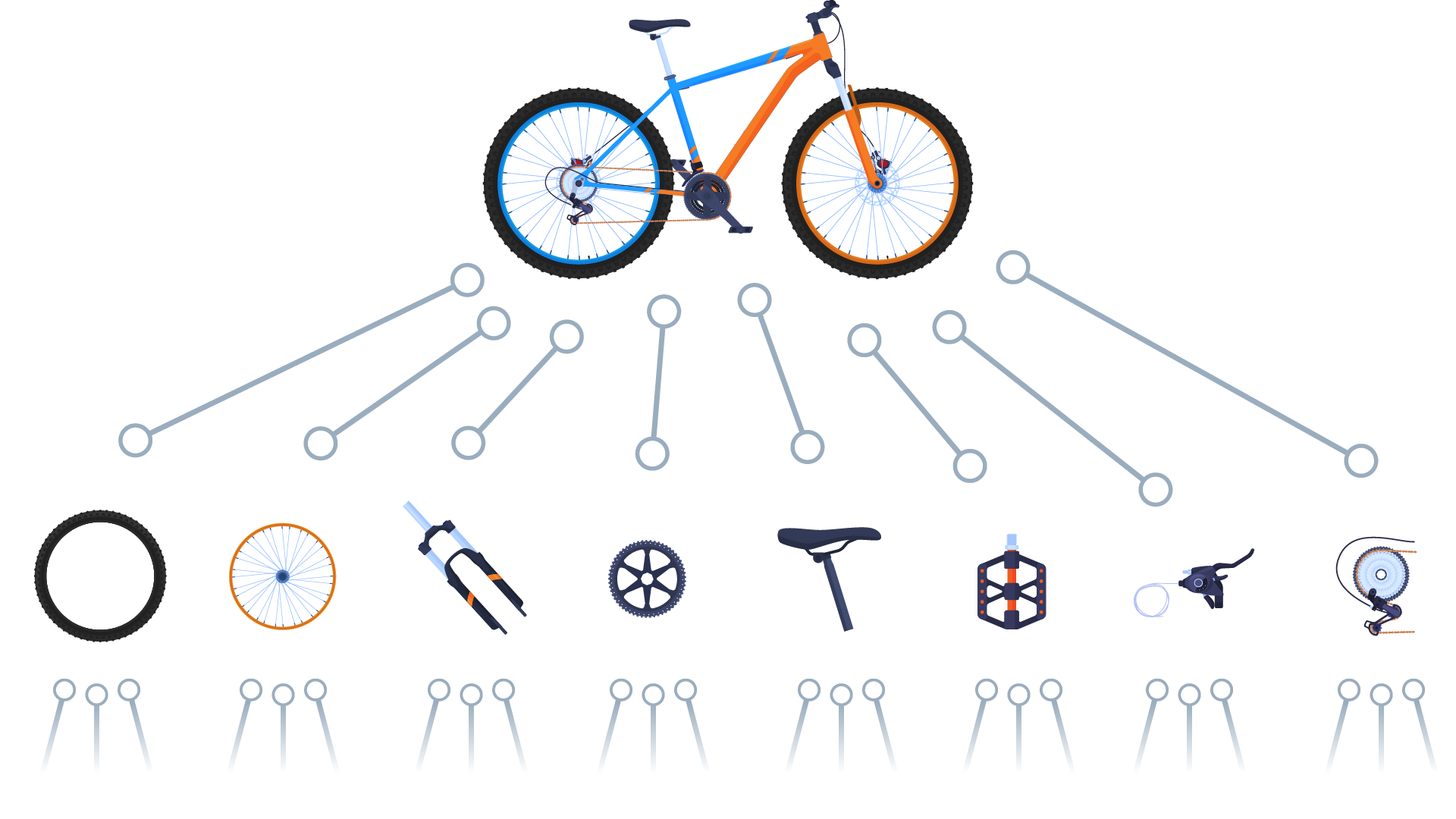

Bills of materials always have a hierarchical structure. At the top is the finished end product, below that are the components, one level lower the subcomponents and all the way down to the raw materials.

Depending on how many levels the bill of materials has, a distinction is made between single-level and multi-level BOMs.

A bill of materials is always made up of a set of defined elements. These include

- the level of the bill of materials

- the article number

- the name

- the description

- the procurement type

- the quantity

- the dimensions

Goals of working with a bill of materials

The overarching aim of a BOM is to create transparency regarding the components and materials required to manufacture a product. This also goes hand in hand with the standardization of the components for the respective product.

This in turn forms the basis for efficient production planning and control and ensures that logistics can provide the right materials and parts in the right place at the right time. This allows you to effectively avoid bottlenecks and ultimately control and plan your costs.

Error-free production with digital bills of materials and weasl

With our weasl worker guidance system, you can provide your employees with work instructions and the associated bill of materials digitally. Create transparent and error-free production processes – with just a few clicks.

Get to know the functions of weasl for yourself – in our free showcase environment.