What does batch size 1 mean?

A batch size is the number of identical products that are manufactured one after the other without interruption or retooling. For example, if you build 100 identical machines one after the other, you would produce in batch size 100.

Accordingly, batch size 1 refers to individual production or special production. Here you produce an individual one-off item for your customer and then change over to the next product.

Why is there batch size 1?

Today we are experiencing a batch size transformation. Although the result is not always batch size 1, production is changing from classic mass production to smaller product batches and one-off production.

Customers' desire for ever more individually designed and configured products is growing. Accordingly, the batch size 1 production strategy is becoming increasingly important in companies - with the aim of meeting these individual customer requirements.

Differentiation from other concepts

In principle, you can always specify a batch size when you manufacture. Even with mass production of 1,000,000 units. Of course, nobody does this, so let's take another quick look at what differentiates the batch size.

Mass production

This refers to the production of very large quantities at low cost.

Series production

Series production is the little sister of mass production. Here, too, large quantities are produced, but they are limited to a certain number. After that, the series is complete.

Mass customization

This is where mass production and individualization meet. Personalized products are produced cost-effectively as part of mass production. This requires a modular product design and flexible production.

Optimal batch size

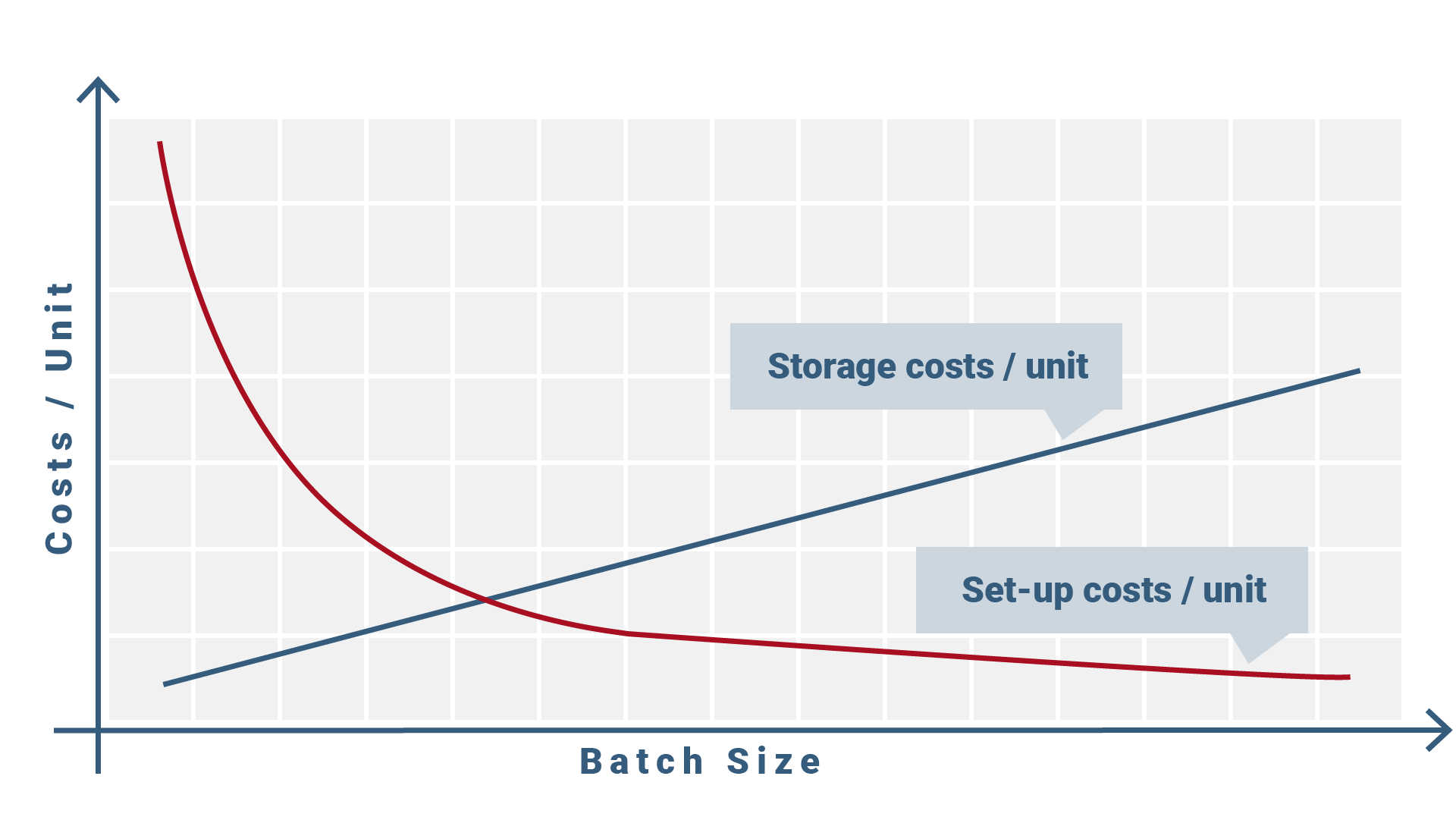

The aim here is to achieve the quantity at which the unit costs (e.g. for warehousing, set-up times and material orders) are lowest. The whole thing can even be calculated, e.g. using Andler's batch size formula.

Flexibility as a prerequisite

In order to be able to respond to individual customer requirements, companies must first and foremost offer a high level of flexibility. Batch size 1 requires the use of modern technologies and processes that make such flexibility possible. These technologies and processes can include

- the use of modern production and information technologies such as ERP, MES, PLM, IIoT, AI or even product configurators for customers

- the automation of processes, e.g. automatic material provision via AGVs or AGVs

- processes such as rapid prototyping and 3D printing

Disadvantages and challenges of batch size 1

Batch size 1 must be affordable not only for the customer, but also for the manufacturing company.

In order to be able to react flexibly to all customer requirements, an increased stock level is often necessary to cover the most diverse eventualities.

The frequent changeover from one product to the next results in increasing set-up costs and set-up times.

The production process itself also becomes significantly more complex and creates new dependencies and conditions.

As a result, production planning must be optimized to avoid longer throughput times. Quite apart from the fact that the flexibility of batch size 1 makes long-term planning more difficult.

Advantages of batch size 1

Batch size 1 also has advantages and, as you might have guessed, these are geared towards the customer. At the end of the day, the customer decides whether to buy from you or not. If they want a customized product and you can't help them with this, they will go to the competition.

Of course, it is entirely up to you and your business model whether you want to offer batch size 1. However, individual production promotes your customer orientation to a considerable extent and can also ensure significantly higher customer satisfaction.

A look beyond the theory

The automotive industry is a prime example of batch size 1. You have probably used a vehicle manufacturer's configurator before. From the seats to the audio system to the color and rims, you can put together your individual vehicle, which is then built according to your wishes.

Batch size 1 is also not a rare guest in mechanical engineering. Do you need a machine for the three-sided machining of shift sleeves for car gearboxes or a separator for small, contiguous parts? Then you will find what you are looking for in special machine construction, which will manufacture the machine you need individually for you.

What's the goal of batch size 1?

Batch size 1 puts the customer at the center of your production. The aim is therefore to fulfill the individual wishes of your customers. Although this poses a number of challenges for your company, customized production increases your competitiveness in the long term.

Mastering batch size 1 with the worker guidance system weasl

To enable your employees to process their orders reliably and error-free in batch size 1, they need a flexible and user-friendly sparring partner that guides them step by step to their goal.

Your employees need weasl. Why? The best way to find out is to take a look for yourself - in our free showcase environment.