Table of contents

What is worker self-inspection? | Advantages | Disadvantages | Types of worker self-inspection | The hard way | The easier way | Practical example | Conclusion

Juli 3, 2024 | Authors: André Nimtz & Maren Fichtner | Reading time: approx. 14 minutes

Worker self-inspection, what is that actually?

Worker self-inspection is an established and particularly production-related quality assurance process that is used both in discrete manufacturing and in the process industry.

During the execution of their work steps, employees check the quality of their production pieces on their own responsibility – this can be done after a certain number of work steps, at particularly critical or error-prone process stages or before handover to the next processing stage.

Through worker self-inspection, intermediate and end products are subjected to continuous inspection according to predefined quality standards – with the aim of avoiding typical errors.

This includes:

- incomplete or faulty processing of components or parts

- incomplete or faulty assembly

- incorrect use of machines or tools

- defects in the installation or removal of parts or components

- defects in the verification of measured values or tolerances

- defects in the verification of documentation

- etc.

The worker records the results during the inspection, creating transparent and traceable documentation.

Operator check & inspection during production

If you find out more about the topic of worker self-inspection, you will certainly come across other terms such as worker self-inspection or inspection during production.

Good news: These terms can often be used as synonyms for worker self-inspection.

Bad news: However, there are readings that assign slightly different meanings to the terms.

Operator check:

Operator checks can focus on more global issues. This includes compliance with production processes and procedural standards throughout the production process and their continuous monitoring (e.g. machine parameters, material flows).

Inspection during production:

Here we are often much more technical. Inspection during production focuses on the specific parameters of the respective production steps. Here, data is checked, measured values are validated and in some cases documented with details of the specific test equipment. Inspection during production is not necessarily a continuous worker task; it can also be part of the quality assurance department's random sample inspections.

Imagine you manufacture 1,000 components, 945 of which are good parts. In this case, worker self-inspection can bring you 55 concrete advantages by avoiding the defects of the 55 bad parts. But even beyond this somewhat tongue-in-cheek example, there are very practical benefits that worker self-inspection can bring to your production.

We have put together four of them:

1. Early fault detection & elimination

If the worker has to validate values or check steps at critical points in their production work, they can also detect errors immediately and initiate the corresponding corrective measures. This not only allows the error to be detected and rectified, but also prevents the worker from further processing a faulty product and ending up with a product that no longer shows its faulty components in the final QA.

2. Cost reduction & increased efficiency

If product quality is consistently controlled, problems can also be consistently avoided. The results are:

- costs for rework and complaints decrease

- your efficiency increases

- your customers are completely satisfied with your consistently high quality

If you read between the lines, you might object: If every worker now also checks everything, they will also lose time. In principle, this is true, but even the total time required for all inspection steps is less than the time and effort required for rework and complaints, which would be necessary for other workers in the event of an error.

3. Gaining responsibility through worker self-inspection

When employees take on quality control tasks, they also take responsibility for the quality of the product. This increases the quality awareness of the workers and can lead to greater safety and satisfaction in their daily work - even to a better identification with the product and the company's goals. In addition, employees also receive direct feedback on the quality of their work as part of the worker self-inspection. Ideally, everything should be in the green at every round, which in turn can have a positive effect on self-confidence.

4. Continuous improvement processes & zero-defect strategy

Worker self-inspection promotes continuous improvement processes through the systematic collection of quality data and defect classes. As soon as you see where defects frequently occur, you can target these points and initiate improvements. This idea can be extended to a zero-defect strategy: If you can rule out errors as early as the production processes through a powerful worker self-inspection, you can also guarantee the highest quality standards in the long term and plan resources for rework.

Anyone talking about advantages must also consider the disadvantages. And, of course, worker self-inspection is not something that you simply set up and then everything works perfectly.

1. The documentation must be correct

When quality assurance tasks are transferred to the worker, the previous complete quality control also disappears from the responsibility of the quality assurer. In principle, this means that all steps of the worker's self-inspection must be documented in a watertight manner, as the final QA must also refer to the results of the worker's self-inspection in addition to its own documentation.

2. New tasks = new challenges

Your workers are not necessarily up to the challenges of a worker self-inspection. The test steps represent additional tasks and increase the complexity of the daily work. This can present the worker with challenges, perhaps even overtaxing them. After all, there was already enough to do and pay attention to. Now there is also the QA. In case of doubt, the worker may not have all the qualifications required for a watertight worker self-inspection. This can also be a challenge.

You may have already guessed it, so we'll keep it short and sweet: we distinguish between analog and digital worker self-inpection. Everything you've read so far has ignored this distinction. But perhaps you've already noticed that some of the disadvantages of digital worker self-inspection can be easily overcome. But more on that later.

Analog worker self-inspection

What does this mean?

- manual execution of the test steps without the support of digital aids

- use of simple testing devices

- manual documentation of test results on paper

- test results depend on the experience and attention of the employee

What are the advantages?

- low to no investment costs for technology

- simple implementation

And what about the disadvantages?

- high training costs

- time-consuming documentation and media disruptions

- prone to errors when transferring results to digital systems

- quality of testing varies from employee to employee

- no transparency or only time-delayed analyses possible

Digital worker self-inspection

What does this mean?

- technological support for the worker, e.g. through sensors, cameras, digital measuring devices

- use of digital testing tools for more complex measurements

- automatic data acquisition

- integration of the selected technology into the existing system landscape

What are the advantages?

- greater flexibility and speed of adaptation to changing production conditions

- reduction in human error

- higher accuracy and reliability of test results

- fast and automatic data acquisition and analysis

- improved traceability and transparency

And what about the disadvantages?

- implementation costs of new software and hardware

- dependence on digital systems

- complexity during implementation

As with so many things, a whole range of skills and knowledge modules are involved in the worker self-inspection. Employees can also receive correspondingly intensive training on the subject of worker self-inspection. This usually takes place at several levels.

Managers and quality assurance staff must build up extensive knowledge about this:

- how QA and worker self-inspection correlate

- how, when and by what means inspection processes must take place in the production process

- which inspection characteristics are to be defined

- how inspection equipment should be calibrated

- which communication strategies are necessary with the workers

- and much more

Employees must also be extensively trained in

- dealing with test instructions

- correct handling and use of measuring equipment

- dealing with defective parts (classifying and cataloging defects, routing defective parts, complaints to suppliers)

- documentation and logging

In addition, employees must be required and encouraged to assume responsibility and a sense of responsibility. These are a lot of challenges that are definitely relevant.

Nevertheless, we recommend that you simplify the path to worker self-inspection - with a digital system.

We don't want to deny that production managers, quality assurance staff and workers need a good level of know-how for worker self-inspection. However, the good thing about it is that they all already have experiential knowldedge that shortens many very specific processes – especially if they are implemented with a standardized digital system. With digital worker self-inspection, you combine the expertise of individual employees with the conditions for successful inspection steps and set up a process that simultaneously empowers and relieves your workers.

6 (+1) recommendations for digital worker self-inspection

Recommendation #1

Introduce a powerful digital system such as a worker guidance system. This will support and relieve your employees and at the same time ensure the automatic documentation of inspection results.

Recommendation #2

Start simple – with simple checks, for example in the form of i.O. and n.i.O. checklists. This will help you achieve initial success and raise your workers' awareness of the new processes.

Recommendation #3

Rely on a system that can display limit values. This allows you to specify an upper and lower limit value for measurements that the worker must adhere to and validate.

Recommendation #4

Provide visual support in the system, for example with comparison images of good and bad parts, technical drawings, videos, etc.

Recommendation #5

Make sure that your employees can provide feedback directly during the process. If there are any difficulties or problems during the audit, you will find out directly and not through a report submitted later.

Recommendation #6

Trained quality inspectors retain sovereignty over the final inspection. Even the best worker self-inspection cannot replace the skills and expertise of the quality assurance engineer. Ideally, they also work with the same digital solution and corresponding inspection plans.

Bonus tipp

Establish continuous evaluation of test data and internal audits. As the data from all inspection processes is now directly available in digital form, it can be used to optimize processes. For example, if a fault always occurs in the same place, you can start to rectify the cause of the fault so that it no longer needs to be checked by the worker in future. Internal audits provide you with information on the success of the inspection measures introduced. For example, you can see which error classes occur particularly frequently, which corrective measures have been introduced, how complaint behavior has changed, and much more.

You can achieve significant initial successes within a short space of time by using a suitable digital system for worker self-inspection. In many cases, a worker guidance system provides the ideal prerequisites for this. After all, you are already guiding your workers step-by-step through the production processes.

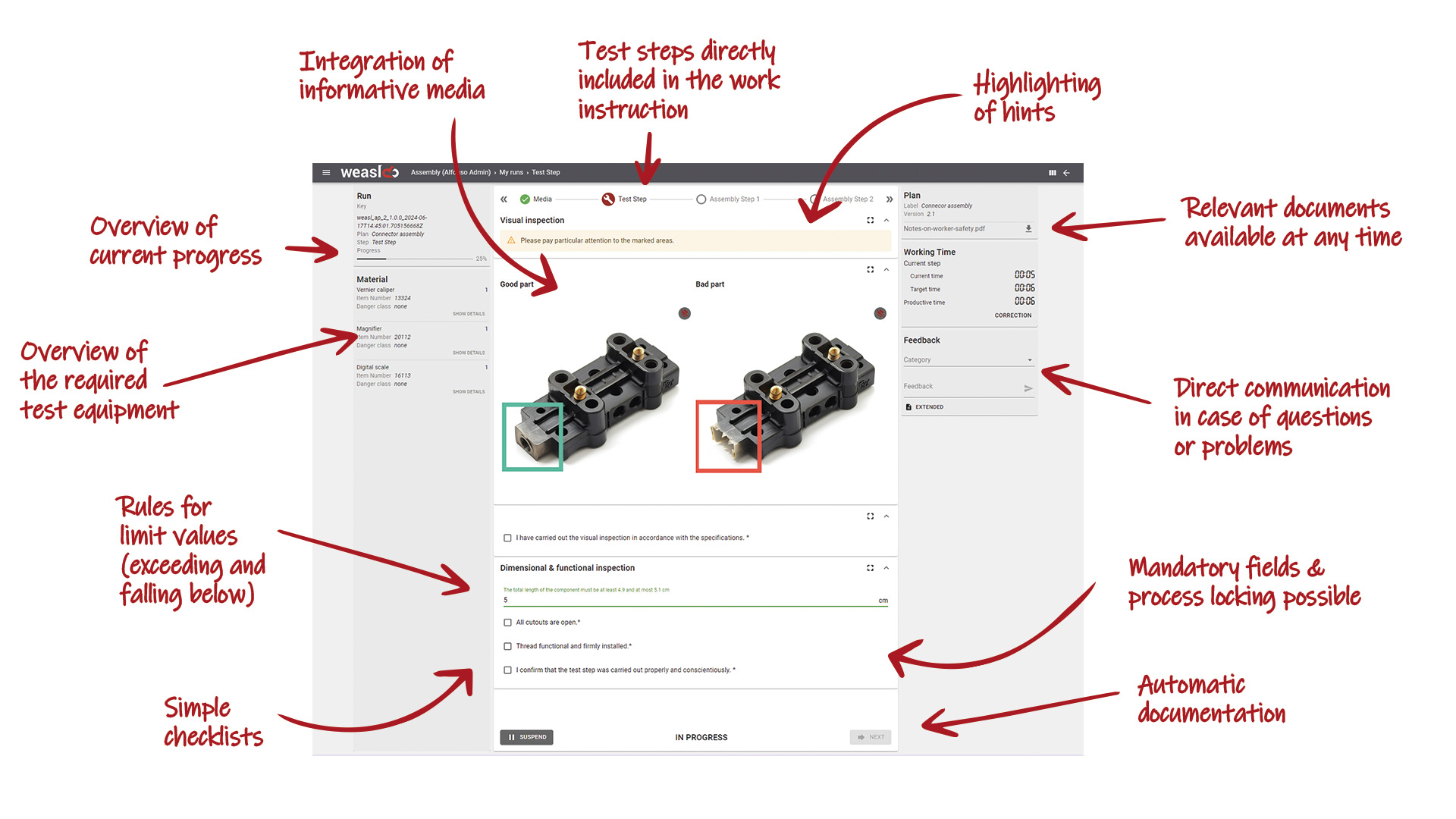

The integration of test steps is just another logical building block here. To make the whole thing a little more tangible, let's take a look at our worker guidance system weasl in practice.

For successful worker self-inspection, weasl offers

- seamless integration of the test steps into the current work instructions (without changing workstations, without restrictions for more complex processes)

- dynamic test steps that can be automatically inserted by the system according to your specifications

- the display of images, videos, checklists, etc. to optimally support the test steps

- immediate or automatic documentation of the test results

- process blocks in the event of impermissible deviations, incorrect entries, etc.

- visual indications when limit values are exceeded, also linked to process blocks if required

- an overview of all required test equipment

- the option to sign test steps electronically (so that the inspector can also consciously confirm that the entries are correct)

- a feedback function for queries or suggestions for improvement

- documents such as design drawings available throughout the complete work plan

- an SPC app for quick visualization and evaluation of test results

In short: with weasl, you can create digital test steps according to your specifications, support your workers with various media during execution and record all relevant data directly in digital form for evaluation in the tool or in connected systems. A worker guidance system with this range of functions is ideally positioned for efficient worker self-inspection.

Conclusion

The more complex assembly and production processes are, the more important worker self-inspection is. This is because it allows you to prevent errors where they occur or are easily overlooked. This in turn saves time and costs for rework and complaints.

For particularly efficient worker self-inspection, we recommend a digital system that optimally supports your workers during inspection steps. A worker guidance system can provide the necessary range of functions for this.

The ideal system for worker self-inspection:

more about weasl in our feature video

Unlock your video access

Watch the video to find out:

- detailed insight into the creation and processing of orders

- overview of the system setup

- details on documentation and review

- illustrative examples directly from the system

- ...

Please note: The video has German audio only but English subs.