September 12, 2024

Authors: Maren Fichtner & André Nimtz

Reading time: approx. 17 minutes

What is shop floor data collection?

As you are reading this text, your production is surely running, right? And on the way to the completed production order, a lot of process and status data is generated that can and should be recorded and saved. This is precisely the task of shop floor data collection or production data collection (PDC), respectively. In addition, shop floor data collection creates a basis for further work with your production data. It enables

- the correct and timely provision of data in order to plan, control, monitor or optimize production processes

- documentation of consumption, costs and other resources and clear allocation to their originators

- answers to basic production questions: Where are which products manufactured by which employees and at what cost?

By the way: There are a lot of terms out there that refer to similar things. You might find "manufacturing data collection" as well as "production data collection" or "shop floor data collection". We use these terms as synonyms throughout this article.

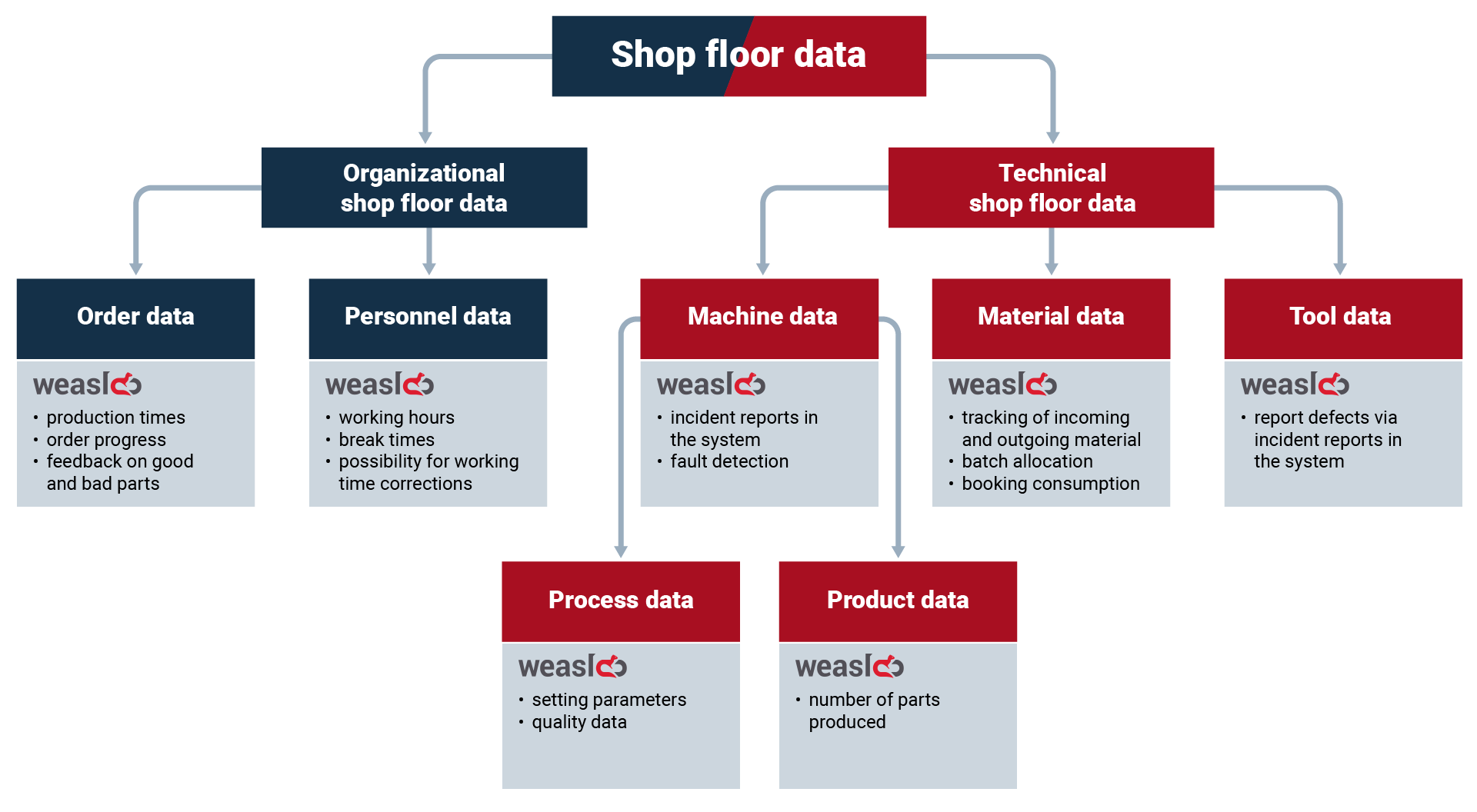

1. organizational shop floor and production data

The first block consists of organizational production data, which in turn is divided into order data and personnel data.

Order data refers - as the name suggests - to data in connection with the production order. This can include

- quantities

- work progress,

- order status

- order-related feedback on work processes

Accordingly, personnel data involves data relating to your employees. This includes

- attendances

- working hours

- access control

- wage costs

2. technical shop floor and production data

On the other hand, we have the large complex of technical production data. Here we are less interested in people and orders, but rather in the machine, the material and the tools.

The recording of machine data focuses, for example, on

- fault messages

- interruptions

- running times

- material consumption

- energy consumption

- number of pieces produced

- maintenance intervals

Machine data can be further subdivided into process data (settings, process parameters, etc.) and product data (number of parts produced, weight, etc.).

Beyond this, material data - i.e. storage locations, material stocks, etc. - and tool data - i.e. tool status, defects, etc. - are also relevant for production data collection.

Machine data collection (MDC)

In the context of production data collection (PDC), you will often also come across machine data collection (MDC) and the question of what the difference actually is. In a nutshell, machine data collection focuses solely on data from machines and systems, while production data collection covers all operating data including machine data.

However, you can set up machine data collection as a stand-alone project if your main aim is to collect information on current machine utilization and availability in order to optimize order planning and increase productivity. You focus on the machines and therefore on recording quantities, fault messages and other machine data.

Now we've talked a lot about data and data collection. Hopefully we haven't lost you in the mass of data that can be collected. Because operational data collection actually has a huge advantage for your company: You can already benefit from the collected data in the short term. Let's take a look at the short-term and long-term benefits.

Short-term advantages of production data collection

- You get an overview of the current status of production and establish real-time monitoring. In simple terms, this leads to noticeably more transparency - about production-related information, machine utilization and the processing status of orders.

- You record fault messages in real time and get an immediate overview of downtimes.

- Based on the data collected, you can immediately optimize the planning of resources, personnel and orders and reduce unnecessary idle times.

- You relieve your employees by having the system record operating data automatically or by direct input.

Long-term advantages of production data collection

- Production data collection allows you to recognize deviations in production at an early stage and initiate countermeasures promptly.

- A look at the data enables you to reliably estimate delivery times and thus ensure a high level of commitment when it comes to deadlines. This in turn increases customer satisfaction.

- The recorded data provides the qualitative basis for use in further systems. It creates the basis for basic fault analyses and can be prepared in a clear and user-friendly way, for example in the form of OEE dashboards.

- With the operating data collected, you can carry out target/actual comparisons and lay the foundation for continuous process optimization.

- With the right system, you can take an important step towards paperless production.

- Production data collection enables optimized personnel planning and machine utilization. This increases productivity and reduces throughput times.

- At the very top, of course: production data collection provides an important building block for securing your competitiveness.

Shop floor data collection is not a modern digitization phenomenon and the corresponding data cannot only be collected if man and machine are optimally networked. But there are significant differences between the methods.

![]()

Let's just call method 1 the “old-fashioned method”: Here, production data is recorded and distributed internally by hand. Of course, this still works to a certain extent today, but this method is highly prone to errors, involves a significant time lag in the processing of information and requires considerable additional effort on the part of employees. To make matters worse, some data - from the machines, for example - remains in the dark.

![]()

Method 2 is therefore the “digitized method”. This is how shop floor data collection should ideally work today: Wherever possible, data is recorded digitally and (partially) automatically, for example in the form of a PDA terminal with RFID or barcode recognition, by sensors and gateways on machines or by mobile data recording with mobile scanners or similar.

This minimizes the risk of errors. Your employees also have the option of entering data manually at recording stations, PDA terminals or in corresponding PDA software on their work devices. This enables structured and systematic data collection in real time and completes the pool of recorded data.

As you can see, modern production data collection is not possible without a technical basis. To approach the topic, you can therefore introduce a PDC system in your production. Such a PDC system consists of hardware such as a PDC terminal, appropriate software for production data collection and the necessary infrastructure for recording, displaying and evaluating all relevant production data.

But before you select such a system, you should clarify the basics.

- Determine the status quo: What data is already being recorded? Is this data sufficient?

- Define KPIs: Which KPIs help to optimize production and should be recorded accordingly?

- Determine the person(s) responsible for the project: Who will benefit directly? Who can effectively drive the project forward?

- Record the need for resources: Is additional hardware required? If so, which ones?

- Define a budget: What can you spend? How much can you save with the system and over what period of time?

- Check the connectivity to the existing IT infrastructure: Which interfaces are required?

- Select suitable PDC software: What does the software need to do? Which functions are essential

- Train the employees: Why does the system exist? How does it help? How is it operated?

The selection of future-proof PDC software plays a particularly important role. The PDC system or the PDC terminal can only be as good as the software it uses. And in the best case, the selected software for production data collection can even be used outside the system and on other end devices. Therefore, make sure that the PDA software

- can be easily installed and accessed, e.g. via SaaS

- offers flexibility and modularity to be able to react quickly to changing requirements

- uses the latest technologies

- comes with comprehensive security measures, such as data encryption and access controls

- comes with optimum connectivity thanks to an open system with open interfaces

- offers high user-friendliness and intuitive operation

- can be used on stationary AND mobile devices

- is compatible with the selected hardware

You have now read about the quantities of data that can and should be collected as part of production data collection. And that PDC systems can provide a powerful, but certainly also quite large-scale answer to your data questions. We would like to suggest an intermediate step that is particularly useful when it comes to recording operating data during manual production processes. When your workers process work orders, they inevitably generate data. This data can be comprehensively recorded and used profitably with a modern worker guidance system.

Our worker guidance system weasl combines essential features from both worlds: For your workers, the system brings access to current work instructions and order-related information, while at the same time offering numerous basic functionalities for shop floor data collection. During manual production, your employees can record relevant operating data in the following areas:

- Order data such as productive times, progress of the work order or order-related feedback on good and bad parts produced.

- Personnel data such as working hours and break times. Working time corrections can also be made.

- Machine data, e.g. in the form of malfunction recording by reporting an incident directly in weasl

- Process data in the form of setting parameters and quality data

- Product data in the form of the number of parts produced

- Tool data in the form of reporting defects directly in the worker guidance system

- Material data through the tracking of incoming and outgoing materials, batch assignments or the recording of consumption

All this data is recorded digitally directly in the system that your workers also use for processing. In addition, the recorded data is immediately available for further processing, transfer to leading systems and detailed evaluation.

Shop floor data collection does not always have to be synonymous with large, expensive software solutions. Basically, you are spoiled for choice as to whether you opt for standard software, custom software or a worker guidance system such as weasl. Your specific needs and goals determine the solution. The following table is intended to provide you with a small decision-making aid.

Criterion | Custom | Standard | weasl |

| Technical aspects | |||

| Operation |

|

|

|

| Hardware compatibility |

|

|

|

| Mobile optimization |

|

|

|

| Connectivity / interfaces |

|

|

|

| Technology |

|

|

|

| Data | |||

| Depth of data detail |

|

|

|

| Data management |

|

|

|

| Plausibility check |

|

|

|

| Data visualization |

|

|

|

| Data evaluation |

|

|

|

| General | |||

| Scalability |

|

|

|

| Support |

|

|

|

| Flexibility |

|

|

|

| Data protection / data security |

| ||

| User friendliness |

|

|

|

Collected operating data can only be really effective if it is used consistently and purposefully. This applies to data preparation as well as visualization and evaluation. It is therefore important to connect the PDC system or the PDC software to other systems. These can be

- Production planning and production control systems (PPS)

- Plant Information Management Systems (PIMS)

- Warehouse management systems (WMS)

- Enterprise resource planning systems (ERP)

- Manufacturing Execution Systems (MES)

- Supervisory Control and Data Acquisition Systems (SCADA)

If you are using one of these systems in your company, plan to integrate it with your new store floor data collection solution. This will pave the way for data-based decisions, for example for detailed production planning. The more data that can be recorded in real time and processed immediately, the more reliable the statements and forecasts will be.

In an increasingly digitalized production environment, solutions can and should no longer be regarded as isolated islands that are only intended for their actual purpose. In the case of PDA software, this is actually ruled out from the outset and yet further trends are also emerging here.

![]()

Analysis of production data through the use of AI and machine learning for early anomaly detection

![]()

Training with VR/AR to illustrate where and how data is recorded during set-up or tool changes, for example

![]()

Increasing cybersecurity requirements and regular review of the security measures of the PDC

![]()

Monitoring and reduction of energy consumption and other resources as well as waste reduction based on the evaluation of production data

![]()

New solution approaches in the software itself, for example through no-code/low-code or cloud migration

What is PDC software?

PDC software is a special software solution for collecting, managing and evaluating operating data. This includes, for example, order status, working times, machine data and reasons for faults. PDC software can differ in the scope of data collected and processed. Some solutions only record certain areas of data, while others provide as complete a picture of operating data as possible.

What is a PDC terminal?

A PDC terminal is peripheral hardware located directly at the machine or the worker's workstation. It can be used to record or display operating data in real time.

What is PDC?

PDC is the common abbreviation for production data collection. This refers to the collection of all process and status-related actual data along the operational production and value creation process. This includes, for example, information on manufacturing processes as well as costs and resource consumption.

What PDC systems are there?

The short answer is that there are many, as PDC systems range from standard applications to individual developments, from pure software to preconfigured software-hardware systems. PDC systems can also be found as part of other software solutions, such as in an MES or a worker assistance system. Essentially, PDC systems differ in terms of their range of functions and integration options.

What is production data?

In production, a distinction is made between organizational shop floor or produdtion data and technical shop floor or produdtion data.

Organizational shop floor data includes

- order data: monitoring of order progress

- personnel data: information on attendance and absence

Technical shop floor data includes

- machine data: information relating to the machine

- process data: factors influencing the manufacturing process

- product data: information about the manufactured product

- material data: information about the material

- tool data: information about the tool

Conclusion

Data is the basis of sustainable processes. It is therefore crucial to consistently record, process and evaluate operating data from your production. Production data collection can start at various points, for example with machine data or organizational data.

The range of solutions extends from complete systems for shop floor data collection to software solutions such as a worker guidance system. For simpler scenarios, such a system is already sufficient to record essential data in real time and initiate sustainable optimization steps.

Shop floor data collection with worker guidance:

Take a live look at weasl

With our free showcase environment, you can take a look at the system and experience live which features and special features weasl has to offer. Click through sample work instructions and gain an impression of where and how weasl can support you with shop floor data collection.

This is what our showcase environment offers you:

- fully functional demo environment

- a large number of concrete application examples

- numerous exemplary step-by-step work instructions

- insights into the look and feel of our worker assistance system