November 25, 2024

Authors André Nimtz & Maren Fichtner

Reading time: approx. 18 minutes

Before we talk about quality assurance:

quality management as framework

“Quality is everyone's responsibility,” the pioneer of quality management, William Edwards Deming, once said. And what is everyone's responsibility should not be left to individual discretion or even chance. Quality must be managed in order to achieve the desired results.

Definition: What is quality management?

Put simply, quality management is concerned with meeting customer requirements for products or services. To this end, quality management provides specific measures and tools that not only serve to fulfill individual customer requirements. They also enable continuous process and product improvement across the board.

Phases of quality management

To achieve this, quality management uses five phases that build on each other:

- Quality planning: This is where the current status in the company is recorded and evaluated and specific measures are derived.

- Quality steering: This is where the defined measures are implemented and monitored.

- Quality assurance: This is where all the measures required to achieve a certain product quality come together.

- Quality control: These are activities that are carried out in production to check the quality of a product.

- Quality improvement: The knowledge gained is finally collected and evaluated in order to make optimizations.

Quality management tools

Now the tools for implementation are still missing and here, too, there are established concepts. The best known are certainly the 7 quality tools that Ishikawa Kaoru defined back in 1943. These include

- flow chart

- check sheet

- histogram

- quality control chart

- Pareto chart

- correlation diagram

- cause-effect diagram

These 7 tools can be used to effectively prevent errors and improve processes.

Why should you implement quality management?

Don't your customers care about quality? If not, then you already have the first answer as to why you should implement quality management: Customers demand certain quality standards. And if they don't actively demand them, they will inevitably expect them.

Can you afford to make mistakes in production? Here, too, you will certainly answer in the negative. With the tools of quality management, you can reduce your error rate and save unnecessary costs due to rework, rejects or delayed delivery times.

And what about the legal framework? Can you manufacture without any legal rules or regulations getting in your way? The probability is low and quality management has the right answer here too. What's more, if your quality management system complies with the DIN EN ISO 9001:2015 standard, for example, this not only confirms your production quality. It also shows your (potential) customers that you place a demonstrably high value on quality - keyword: competitive advantage.

DIN EN ISO 9001:2015

Quality not only has its price, but usually also its standard. And these are issued by the International Organization for Standardization - ISO for short. This organization is the world's leading authority for safety and quality standards in services and production, which sets standards for various business and production processes.

For companies, this means that they can obtain ISO certification. The prerequisite for this is that the company proves itself in external audits. If a company can therefore ensure and prove in an audit that it offers consistently high-quality products and services, the company meets the requirements for quality management systems and can be certified in accordance with DIN EN ISO 9001:2015.

We at iSAX are also certified according to ISO 9001.

Let's talk about our actual topic: quality assurance in production and manufacturing. Well, let's say: We need to talk about two things - quality assurance and quality control.

“Aren't they the same thing?” some people might ask. And the Internet also likes to lump the two together. Strictly speaking, both quality assurance (QA) and quality control (QC) are independent concepts and as such are components of quality management that differ from one another in terms of their focus and tasks.

Quality assurance (QA) | Quality control (QC) | |

|---|---|---|

| Definition |

|

|

| Goal |

|

|

| Main focus |

|

|

| Time of implementation |

|

|

| Methods |

|

|

| Advantages |

|

|

Quality assurance is therefore the proactive, organizational process, while quality control is the reactive doing during production and assembly. In the rest of this article, we will focus on quality assurance - in other words, the measures and processes that you can establish to ensure high quality standards. We will look at the practical implementation in the form of quality control at another time.

So now we know that in quality assurance we don't talk about whether a thread diameter fits or whether screws have been tightened to the correct torque, for example. But what are the tasks of quality assurance in production?

The tasks of quality assurance include

- the definition, planning and implementation of systematic testing concepts - including customer-specific adaptations as required

- test equipment management

- process and workflow monitoring

- monitoring and ensuring that tests are carried out properly

- employee training on the content, measures and objectives of QA

- initial sample test reports

- supplier evaluations

- documentation of all measures

- processing complaints and customer communication on quality-related issues

- as well as continuous improvement processes (CIP) for long-term quality improvement

Quality assurance in production

Let's take a look at the process-related quality assurance options you have in production. Production is much more comprehensive than the sub-area of manufacturing and includes all processes and steps required to manufacture a product. The methods you can use are correspondingly comprehensive.

Lean Management

Speaking of lean: when it comes to lean processes, you quickly end up with lean management. This is primarily about optimizing processes by eliminating waste and unnecessary process steps or sub-processes. The aim is clearly to increase efficiency and quality assurance.

Value stream method

With the value stream method, you analyze the material and information flows in order to identify optimization potential and plan quality-relevant stations and information. The aim of the value stream method is to introduce a lean production system.

Supplier audit

As the name suggests, during a supplier audit you turn to your suppliers and check whether they have quality protocols and supply high-quality materials and components. The aim behind this is to only use materials, raw materials and components for production that meet the required quality standards.

Six Sigma

Six Sigma is an approach to process optimization that consists of two key approaches - the DMADV and the DMAIC approach. DMADV stands for “Define, Measure, Analyze, Design, Verify” and is used for the development of new processes and products. DMAIC, on the other hand, stands for “Define, Measure, Analyze, Improve, Control” and refers to the improvement of processes. The aim is to reduce the error rate in production to zero errors.

Quality assurance in manufacturing

Manufacturing is a sub-area of production and involves the processing of raw materials into parts and components, which are then assembled into a final product. Quality assurance processes should also be part of production, but with specific methods.

Statistical process control (SPC)

As part of statistical process control (SPC), you define quality-determining factors and have samples evaluated using a progression graph with limit values. This gives you transparency about quality deviations and fluctuations so that you can intervene in the process promptly and rectify problems.

Failure mode and effects analysis (FMEA)

The failure mode and effects analysis is concerned with finding the reasons why process steps can run incorrectly. These analyses are also used to determine a risk priority number for each possible error, which takes into account the probability of error, the consequences of the error for the customer and the probability that the error will not be noticed. The higher the priority number, the more serious the error. The aim is to avoid error causes with a high priority number.

Quality assurance in assembly

As a step in production that deals with the assembly of individual parts into a finished (partial) product, assembly is just as important as production. Here, too, quality assurance must use the appropriate methods. These can include

Quality-compliant work instructions

Provide your employees with digital work instructions with meaningful details for each assembly step so that errors can be effectively reduced.

Cleanliness in the workplace

It sounds trivial, but to ensure that products are not contaminated, scratched or damaged, the workplace must be kept clean. This in itself is a fundamental method of quality assurance in assembly.

Poka Yoke

Poka Yoke is Japanese and stands for the prevention of unintentional errors. By taking certain product-specific mechanical or electronic precautions, for example, you can prevent a component from being assembled incorrectly in the first place. This means that you do not give your employees the opportunity to make a mistake in certain aspects in the first place.

Design for assembly

During the design or construction of the product, ensure that your workers can assemble components easily, safely and without errors. In this way, you exclude the possibility of reworking and complaints later on in the product design.

Automated image processing with camera systems

The use of certain technologies can also be a means of quality assurance. With the help of cameras, for example, you can check and verify the accuracy of fit, completeness and surface quality of workpieces and products.

Inline and offline testing

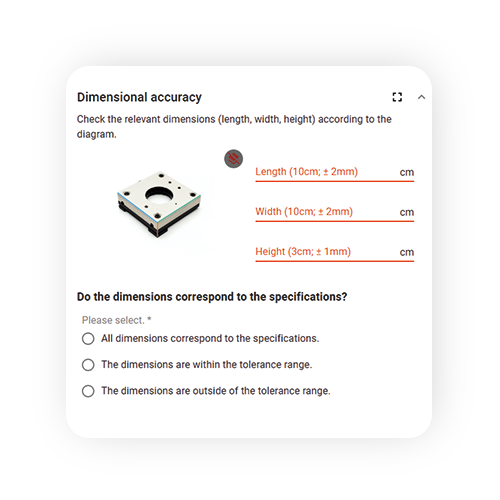

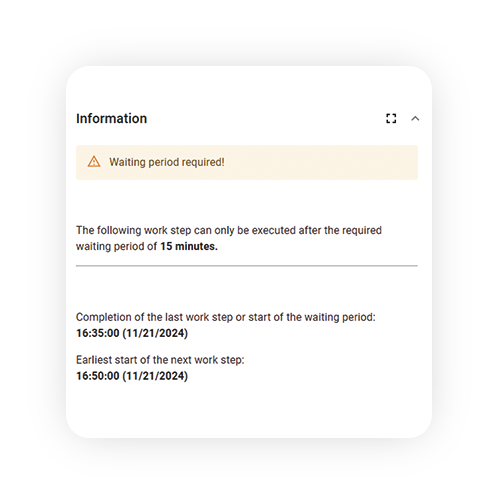

Carry out quality inspections during or immediately after assembly - for example as a dedicated work step in the digital work instruction. This enables your employees to carry out worker self-inspection and thus detect errors promptly during the assembly process.

That was a lot of methods for quality assurance and you may now be asking yourself the question: “What do I do with them now and what is really effective?” Let's break it down again to the specific to-dos that you should have on your screen - in a flexible order.

- Introduce a quality management system in which all data, information, measures and learnings converge.

- Standardize your manufacturing processes, for example with Standard Operating Procedures (SOP). Standard processes established in line with quality standards are the key to continuous quality assurance.

- Train your employees in quality standards, procedures, tools and their use. Only those who know how things work and what needs to be taken into account will develop an awareness of quality objectives.

- Monitor and optimize processes. Just because processes are standardized does not mean that they run optimally. Keep an eye on them and make adjustments where necessary.

- Ensure that you receive high-quality materials and components from your suppliers. If the quality in the supply chain is poor, the end product will also be poor.

- Implement quality controls in the production process and enable your workers to carry out worker self-inspection.

- Create the greatest possible transparency and traceability in your production. This is the only way to find out for sure where the devil is at work.

- Carry out internal audits to put your processes and quality assurance measures to the test.

Up to this point, we haven't even talked much about digital technologies. Of course, you can also tackle quality assurance in your production largely without the possibilities of digitalization. But that basically means

- You do everything by hand and write down the results.

- You document on checklists and the like and transfer everything to the system later.

- You spend a lot of time monitoring and improving processes.

- You accept media disruptions and errors during data transfer.

- You can only identify and rectify errors with delays.

However, digitization opens up numerous possibilities for optimum quality management and error-free production. For example:

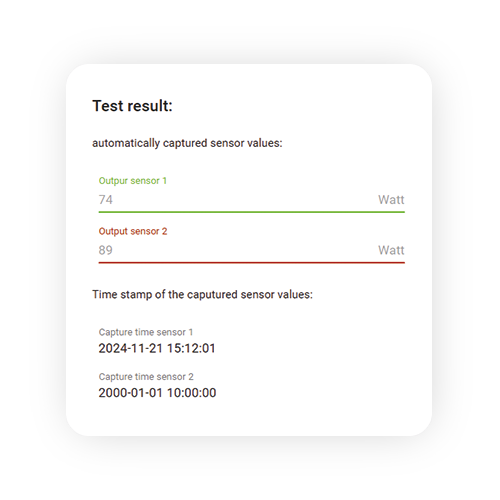

- sensors or cameras to automate quality inspections

- big data and data analytics for pattern recognition of error trends

- AI and machine learning for predicting possible quality deviations

- digital twins to simulate production processes and identify potential sources of error

- worker guidance systems to support manual activities and ensure the reliable execution of activities, including worker self-inspection

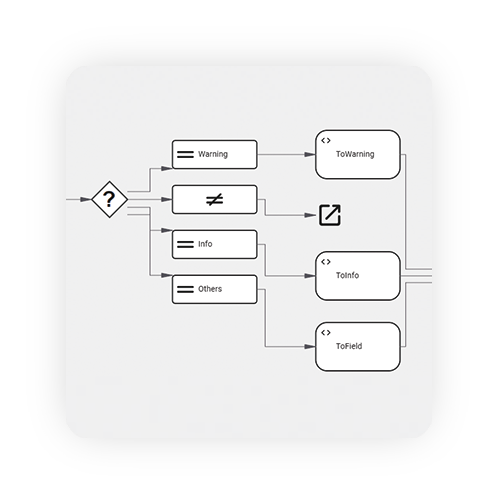

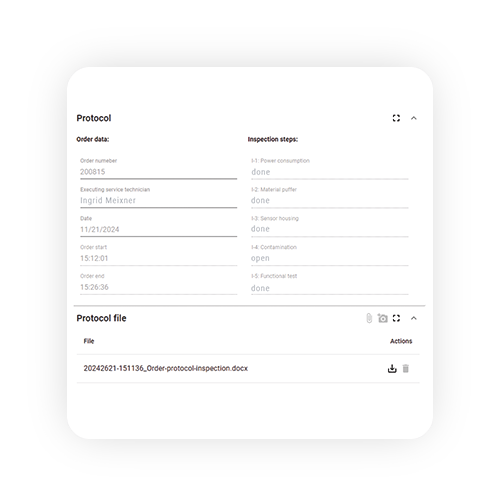

Our worker guidance system weasl relieves your employees of all manual tasks in production and assembly. Beyond this, it offers numerous options to support you in the implementation of quality assurance processes in your production. What exactly does that look like?

Conclusion

In today's highly competitive and often multi-variant production environment, the need for reliable quality assurance is beyond question. Establishing appropriate processes is the be-all and end-all. These start with your supply chains and include process standardization, training and audits.

Digitalization provides you with numerous tools to do this. You can successfully establish key processes with solutions such as a worker guidance system. It is important that you create transparency, establish standards and keep a critical eye on process optimization.

Make quality assurance much easier – with weasl

Your workers contribute to the quality of your manufactured products in a significant way. And with weasl, you ensure that this contribution always meets the high demands of your customers.

Take a look at the system and see for yourself – with our free showcase environment.