Table of contents

What is predictive maintenance? | Maintenance types | How does it work? | Advantages | Challenges | Steps for implementation | What comes after that? | FAQs | Conclusion

Last updated: August 16, 2024 | Authors: André Nimtz & Maren Fichtner | Reading time: approx. 19 minutes

Predictive maintenance: your advantage over the competition

Unplanned machine downtime can quickly cost you several thousand euros per minute - while the competition continues to produce. A few years ago, experts assumed that up to 70 percent of all unplanned downtime could be prevented with predictive maintenance.

Technological development has progressed and predictive maintenance has become an important and direct cost-saving component of Industry 4.0. The networking of machines and processes, the use of data and the resulting proactive maintenance of your machines will ensure your economic success.

Predictive maintenance answers the question: “What will happen to your machines and when?” By linking, visualizing and analysing machine and production data, the optimum time for machine maintenance and servicing can be predicted.

The result: the machine no longer suddenly stops for any reason. By continuously measuring and analyzing machine data:

- identify possible wear or deviations of the equipment in the production process

- increase production reliability and the efficiency of maintenance measures

- maximize the overall equipment effectiveness (OEE).

This makes it possible to plan downtimes and minimize unplanned downtimes. With predictive maintenance, you only service machines when it is necessary and planned on the basis of data.

From firefighter to strategic planner:

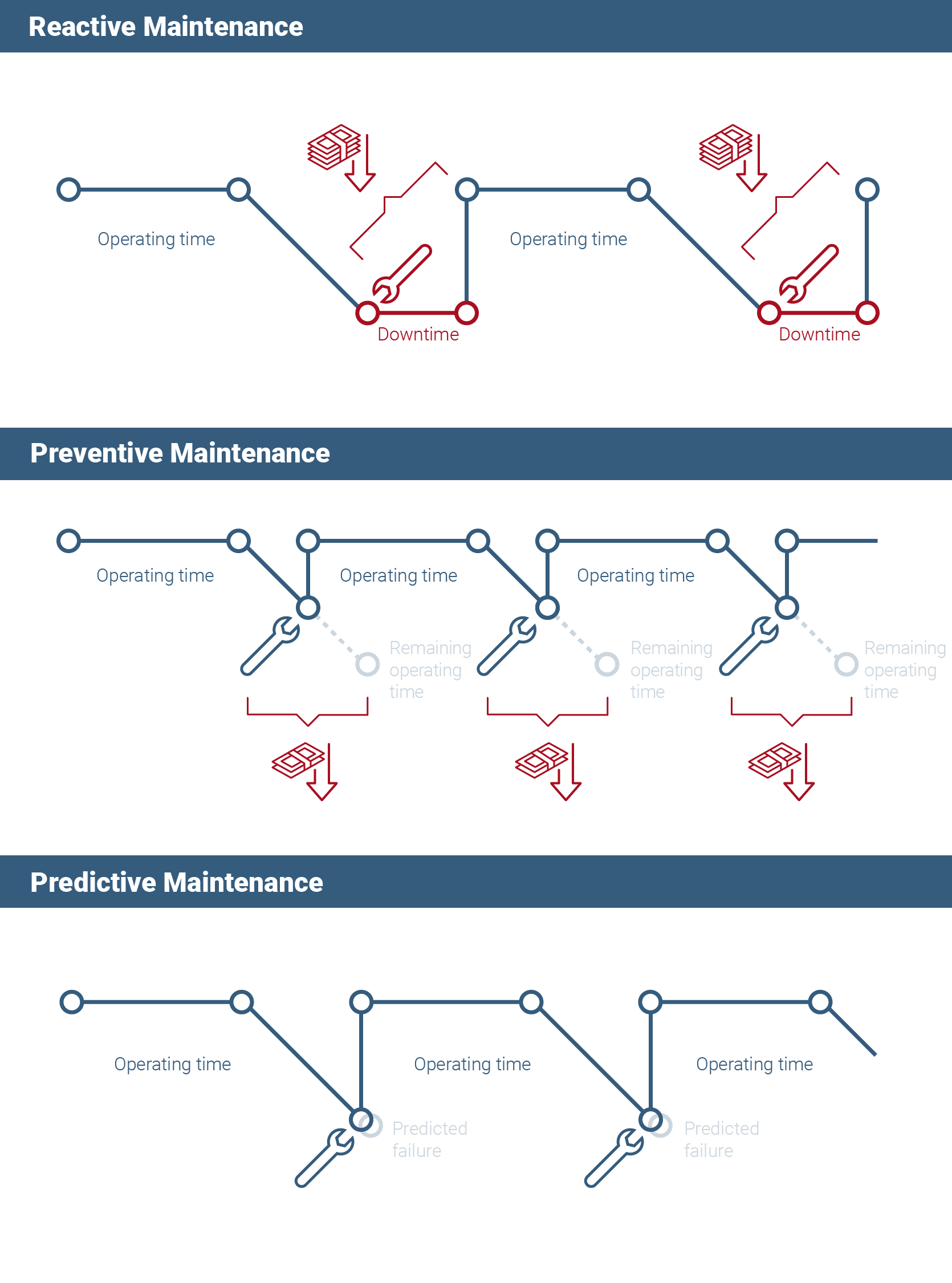

maintenance types at a glance

Machine maintenance is an integral part of every manufacturing company. Companies often only react to the behavior of their machines and systems: if a defect occurs, the machine is at a standstill until the fault is rectified. Figuratively speaking: There is a fire and you have to put it out first.

However, it saves time and money to plan maintenance on the basis of data. This allows you to intervene before the machine comes to a standstill and also optimize the mean time to repair (MTTR) in the long term. We present the advantages and disadvantages of common maintenance approaches in more detail.

![]()

Predictive maintenance

Based on recorded operating and process data and the actual condition of the machine, a prediction is made as to when the machine or system requires maintenance.

Advantages

- maintenance can be planned

- downtimes are reduced to a minimum

- the service life of the machine and parts is increased

- personnel deployment and spare parts can be planned precisely

- cost savings compared to routine and interval-based preventive maintenance

Disadvantages

- machines must be made fit for data acquisition

- initial costs

Your role

You are no longer a firefighter but a strategic planner. You prevent fires before they start, based on collected data.

![]()

Preventive maintenance

In preventive maintenance, machines and systems are serviced according to a set schedule. Historical data and empirical values often serve as a basis.

Advantages

- extended service life of the system

- real failures can be avoided

- cost savings possible compared to reactive maintenance

Disadvantages

- machine parts with remaining service life are replaced

- even running machines without risk of failure are taken off the grid - unnecessary downtimes are caused

- any worn parts are ignored

- unplanned breakdowns are still possible

- comparatively high costs

Your role

You are the experienced firefighter who provisionally extinguishes the fire to prevent it from starting. But a fire could still break out.

![]()

Reactive maintenance

Machines and systems are operated without insight into data and statuses until maintenance is required. Maintenance is carried out when the damage occurs.

Advantages

- system can be operated up to maximum production output

- no further investment is required for data acquisition and co.

Disadvantages

- repair costs can significantly exceed production value

- long, unpredictable downtimes occur

- the damage can have scattering effects on other machine parts

- usually only symptoms are remedied, not the causes

- high financial burden

Your role

In this case, you are the fireman who can only extinguish the fire.

The path to effective predictive maintenance is certainly no walk in the park. Your specific goals, the existing, usually heterogeneous machinery and complex production processes place high demands on the implementation strategy. But the effort is worth it, because with predictive maintenance you can significantly and sustainably influence your production performance.

There are 5 points you should bear in mind during implementation:

![]()

Creating a data basis for predictive maintenance

The right data basis is the foundation for your path to predictive maintenance. How you achieve this database depends on how far your machines are already digitized. Equip your machines and systems with the necessary sensors and measuring devices. Introduce a data catalog to maintain an overview of the data and record the status data of your machines and systems (condition monitoring). This includes all functional data such as speeds, temperature, noise, fluid levels, pressure, bearing vibrations and power consumption.

Please note that production is not the only relevant area. Other areas such as product management, IT and maintenance should also influence this database.

And don't forget the context data: for example, what is the temperature, humidity and contamination at the place of use? How many cycles has the machine completed? What data is available on downtime periods and causes and reports of faults? What data do the maintenance logs provide?

The larger the database and the more intelligent the analysis algorithm, the more reliable the results.

![]()

Setting the right focus

Machine data, process data, environmental data from your production: to effectively predict unplanned downtimes, you need to know what information you want to gain from the data you collect. Define the desired insights as clearly as possible, because only then can you avoid wasting a lot of time collecting the data. Collect and process exactly the data that is important for your predictive maintenance.

![]()

Transparency and visualization

Once you have created the data basis and defined the knowledge objectives, you need to make your data readable. Up to this point, the data from your machines and systems only runs into your server or into the cloud. With targeted visualizations, you can create transparency in your processes and enable threshold and trend analyses. The data from different systems may have to be homogenized first, but then the first optimizations can already be achieved by manually comparing the ACTUAL data with the TARGET values.

![]()

Recognize connections

Up to this point, sensors, gateways and software have done their job. Now you can use machine learning algorithms and artificial intelligence to evaluate historical machine data and find the causes of previous failures or anomalies.

Training data is used to teach a model that automatically recognizes error patterns. In turn, you use this model in day-to-day production to automatically make forecasts and detect wear in live operation. The model continuously scans and analyzes the data streams provided (streaming analytics).

![]()

Carry out maintenance proactively

The resulting prediction model enables anomalies to be detected at an early stage. Based on this, you can proactively carry out targeted maintenance and repair measures and prevent unplanned outages.

Reducing (maintenance) costs

Predictive maintenance helps you to save costs on various levels. Firstly, there are the massive costs per minute of unplanned downtime, which we have already discussed above.

Predictive maintenance also enables optimized spare parts handling. In concrete terms, this means that you use wear parts in your machines until they need to be replaced. You make optimum use of the service life of the part and replace it as planned before it causes downtime.

This also reduces the cost of stocking the corresponding individual parts. Last but not least, predictive maintenance enables better resource planning so that you can keep personnel and material costs for maintenance to a minimum.

Maximize machine uptime & reduce downtime

If you can predict when a component will put your machine out of action, you can prevent failure. This prevents downtime and increases system availability. However, regular predictive maintenance also increases the overall service life of your machines and systems.

You prevent the failure of one component from affecting other components. Predictive maintenance also enables you to plan maintenance work in such a way that your production is only minimally affected, if at all.

Improved safety in the working environment

If data is automatically recorded on your machines and conditions are monitored, manual measurements are no longer necessary. Interventions in the machines are no longer necessary. Plant safety is increased and accidents can be avoided.

Heterogeneous machine parks

Very few companies have a homogeneous and sufficiently digitized machine park from which the required data can be easily collected. This restricts the necessary data flow. This can be counteracted either by retrofitting or purchasing new machines. Both incur costs.

Data silos

Data often exists in silos that are tied to a specific purpose and are not open for global use. Such data silos need to be broken down for predictive maintenance. Data must be democratized to enable centralized access to all relevant data.

Big data

As soon as you can continuously record process, production and context data, this data also comes in in large quantities - keyword big data. This data must therefore be processed further. You need the appropriate resources for this.

Historical data

Historical data is an essential prerequisite for predictive maintenance. If you only start collecting data today, you will lack this data. But even if you have already collected historical data, there is a risk that rare incidents will be overlooked because the data does not go back far enough.

Our proposed solution to these challenges

Let's put it quite simply: Talk about it - with:

- your machine manufacturers and find out how you can also make existing machines fit for predictive maintenance

- digitalization experts who can use their experience and understanding of technology to outline the most sensible way to achieve predictive maintenance

- your colleagues about which processes are worth investing in predictive maintenance and carry out a cost-benefit analysis.

These discussions will most likely result in practicable solutions for predictive maintenance in your company.

The question of data sovereignty

Who owns the machine data? The manufacturer or you as the operator? Your machines could often already provide you with process or status data. But without additional sensors, you can't access it because the manufacturer doesn't allow access or only sells it at a high price. And this is despite the fact that the data is generated by your work with the machine.

The question of data sovereignty is to be regulated by the EU Data Act from fall 2025. This will define who has access to which data and under what conditions. The aim is to ensure the fair and democratic use of data. Data that you have generated should also be made usable for you. This can benefit your efforts for beneficial predictive maintenance.

Our recommendation:

Do not base your pilot project on the amount of data available, but on the real, serious problems in your production.

Step 1: Evaluation & narrowing down

It is best to start with a joint workshop with all internal stakeholders. Bring together all the employees who can assess which use cases are suitable for predictive maintenance. Evaluate the use cases according to relevant criteria such as

- technical improvement potential

- financial savings potential through predictive maintenance

- factors influencing product quality and wear

Once you have identified a use case, define the scope of the pilot project. This means: do not tackle the entire production line straight away, but focus on individual, particularly problematic process steps.

Our recommendation:

Place particular focus on causalities. You can often derive the first “quick wins” and make initial process optimizations during this phase.

Step 2: Get to the data

Enlist the support of digitalization experts who have experience with data analytics and start collecting data. Record historical data and make it available for analysis. This may already reveal initial patterns that will later form the basis for streaming analytics.

Ensure a regular exchange between your internal experts and the external data scientists on the results of the data analysis.

Reading tip:

Gain an insight into how the implementation of predictive maintenance based on the IoT platform ThingWorx can look in concrete terms.

Step 3: Implementation

The foundations have been laid, so you can now think about the technical details together with your implementation partner. What should the predictive maintenance architecture for your plant look like? Who should be provided with what information, when and how? What tools do your employees need to be able to work effectively with the data?

This results in the specific technical realization and implementation of the predictive maintenance system for the production steps you have selected.

Advanced IIoT technologies

The key lies in the data - and not just for predictive maintenance. The more data you collect from machines and systems, the more accurately you can create a digital image of them. This di

- changes in the system can be tracked continuously

- threshold values can be defined and problem areas visually highlighted

- maintenance measures can be simulated and maintenance plans optimized

You can also have automated inspections carried out by robots on the basis of data. This is particularly useful at production points that are difficult to access or potentially dangerous.

An additional means of optimizing maintenance processes can be found in AR tools, which virtually display the maintenance steps directly on the respective machine.

Prescriptive maintenance

Do you remember the maintenance types and the question of whether you are a firefighter or a planner? With prescriptive maintenance, you can leave both roles behind. With this technology, the system not only predicts failures, but also provides the recommended measures. You can even initiate measures yourself.

This saves you a lot of time thanks to self-learning automatisms, minimizes downtimes, maximizes service life and operating time and significantly reduces the amount of analysis required by your service technicians. However, prescriptive maintenance requires a high initial outlay for software and equipment and is extremely complex to implement.

Prospects for machine manufacturers

So far, we have looked at predictive maintenance through the eyes of the machine operator. However, predictive maintenance can also be interesting for machine manufacturers - not only in terms of the production of the machines themselves, but also with regard to new business models.

Machine manufacturers can already make the newly delivered machine available as a digital twin in machine and customer portals. In addition to status monitoring and fault reports, this also opens up opportunities for after-sales services. For example, spare parts or additional services can be offered as required or ordered by the machine operator.

When is predictive maintenance worthwhile?

Predictive maintenance is particularly worthwhile in the following cases:

- for machines and systems that are critical for production or safety

- if you incur particularly high costs due to unplanned downtimes and repairs

- if spare parts or qualified maintenance personnel are difficult to obtain

- if you only set maintenance intervals according to the manufacturer's specifications or calendar instead of actual requirements

Why is predictive maintenance important?

Predictive maintenance is important because it can reduce unplanned downtime and repairs. Monitoring machine data makes it possible to identify causes of failure at an early stage and initiate maintenance or repair measures. This improves the efficiency of maintenance processes, reduces costs and increases the availability of machines and systems, which in turn has a positive effect on productivity and added value.

What is predictive maintenance?

Predictive maintenance is a maintenance strategy designed to identify potential problems in machines and systems before they lead to downtime. By monitoring and analyzing machine data, deviations and anomalies can be detected and predictive models can be developed in order to

- determine the optimal time for maintenance and repair

- minimize costly breakdowns

- extend the service life of machines.

What do you need for predictive maintenance?

Several components need to be combined for predictive maintenance:

- data acquisition systems to collect machine and plant data

- analytical tools/algorithms for data processing and pattern/anomaly detection

- prediction models to predict the optimal maintenance time

- a suitable infrastructure for storing, processing and analyzing large volumes of data

- trained employees for data analysis and the interpretation and implementation of maintenance and repair plans

Conclusion

Predictive maintenance can be a key lever for your competitiveness. By planning downtimes based on data and preventing production losses, you can reduce your costs and increase efficiency. However, predictive maintenance is not the most trivial digitalization approach.

You need a comprehensive data basis and appropriately trained models that are responsible for the forecasts. To do this, we recommend working with experienced data scientists and digitalization experts.

We develop the optimum solution for you

"The use of digitalization for predictive maintenance reduces downtimes and repair costs. Faults are detected at an early stage and maintenance measures can be planned more effectively thanks to real actual data.

It improves the operational efficiency and service life of machines, which conserves long-term investments and resources. Digitalization in predictive maintenance can increase the overall productivity and thus the competitiveness of your company."

Sven Rotzsche | Head of IIoT Solutions | iSAX GmbH & Co. KG

Where do you stand? What requirements have you already met and what do you still need to do to get predictive maintenance up and running? Or is a completely different approach worthwhile for you? Drop us a message and tell us about your plans and goals.