December 19, 2024

Authors: André Nimtz & Maren Fichtner

Reading time: approx. 15 minutes

New Machinery Regulation 2023/1230: a brief classification

Something big is coming your way and it also has a big name: „Regulation (EU) 2023/1230 of the European Parliament and of the Council of 14 June 2023 on machinery and repealing Directive 2006/42/EC of the European Parliament and of the Council".

The - in short - new Machinery Regulation 2023/1230 saw the light of day in the EU in 2023 and will regulate the placing of machinery on the European market from January 20, 2027. It is intended to standardize procedures and take into account the numerous technological developments of recent years.

It is also intended to replace the outdated Machinery Directive 2006/42/EC, which, as a

- which, as a “simple” directive, is far less binding,

- has been around for more than 15 years and

- does not include significant developments.

Now the question arises: does the new Machinery Regulation also affect you and your company? Do you build

- machines or partially assembled machines?

- machine-related products such as interchangeable equipment, chains, ropes, etc.?

- digital components such as software and control systems?

If so, then your company also falls under the scope of application.

Progress in digitalization in Germany

Even if companies are not yet fully digitized or even automated, digitization has left its mark on production in recent years:

- People work together with robots and cobots.

- Machines have become network-capable and therefore smart.

- Autonomous machines and remote services are opening up new IIoT worlds.

- Software updates can have a significant impact on safety in companies.

The requirements for health and safety protection have grown as a result and are to be regulated in a binding manner with the new regulation. Machine safety should be guaranteed despite new technologies and, more importantly, users should be given the assurance that they can trust even the most modern networked machines without restriction.

Saving costs

The new Machinery Regulation also aims to optimize processes and reduce administrative work and costs for manufacturers. Administrative processes are to be simplified by increasing the use of digital formats. We will come to this in more detail later.

Harmonization and standardization

In contrast to the previous Machinery Directive, the new EU Machinery Regulation 2023/1230 applies to all EU countries to the same extent. Once it comes into force in January 2027, the regulation will be binding for the entire EU. This goes hand in hand with efforts to establish a standardization of European safety requirements for machinery and to establish processes that are compliant with the EU's New Legislative Framework (NLF). (see info box)

The New Legislative Framework (NLF) of the EU

The EU's New Legislative Framework (NLF) is a regulatory framework for European product regulation.

This framework defines

- which rules exist for the conformity assessment of products. These rules are ultimately used to check whether or not a product complies with EU regulations and standards.

- which organizations are permitted to carry out tests and which framework conditions apply to the inspection and accreditation of these organizations.

- how market surveillance is regulated. This includes, for example, how non-compliant products can be identified and what measures must be taken to remove non-compliant products from the market.

New rules, new obligations. And these apply both to manufacturers and to other parties involved in the sale of the machine or associated parts. In technical jargon, this is generally referred to as economic operators. The following table shows which economic operator must fulfill which obligations.

Economic operators | Duties and tasks |

|---|---|

| manufacturer |

|

| authorized representative |

|

| importing companies |

|

| trading companies |

|

The approach of regulating the introduction of machinery through legal requirements is not new. The Machinery Directive 2006/42/EC has been in force within the EU since 2009. However, it is only a directive and not a regulation and is therefore freer to implement.

The Machinery Directive focuses primarily on the manufacturers of machinery and defines requirements for safety in the interaction between man and machine. These include

- essential health and safety requirements including requirements for design, ergonomics, safety equipment and user information

- procedures for conformity assessment and CE marking with a view to issuing the declaration of conformity and affixing the CE marking

- requirements for documentation and instructions for use, i.e. the provision of technical documentation and comprehensible instructions for use in the national language of the user

A word in advance: We don't want to go through the 100-page legal text in detail here and discuss every change. In this article, we are concerned with the changes for manufacturers of machinery and associated parts.

And a second word in advance: As you have already read, the Machinery Regulation 2023/1230 is to be binding in all EU countries. Unlike the Machinery Directive 2006/42/EC, the regulation does not have to be transposed into national law first. It will therefore apply in its written form from January 2027. This also includes the extended scope to include software, for example.

But let's take a look at some of the details.

1. Definition of conformity assessment procedures

The new Machinery Ordinance regulates conformity assessments according to clearly defined procedures, which in turn must comply with certain standards. There is (as yet) no specification as to when which procedure must be used. However, certain procedures are explicitly recommended for certain products. These procedures include

Internal production control

Here, the manufacturer himself ensures that his machines are manufactured in accordance with applicable regulations. To this end, they carry out internal checks during production. An external inspector is not absolutely necessary.

EU type examination certificate (formerly EC type examination certificate)

In future, EU type examinations can be carried out by notified bodies for machine types. If all relevant requirements have been met, the notified body issues a corresponding certificate confirming that the prototype complies with the safety and health requirements of the regulation.

Internal production control with supervised product testing

Here, internal production controls are supplemented by tests by notified bodies.

Individual testing (new in the course of Regulation 2023/1230)

In future, the inspection of each individual machine by an external inspector will also be one of the possible conformity assessment procedures. The inspector does not inspect the type, but the manufactured machine for compliance with the regulations.

Comprehensive quality assurance

As the name suggests, this procedure goes far beyond individual tests. With comprehensive quality assurance, a notified body monitors the entire manufacturing process to ensure the conformity and quality of the machine.

2. Assessment of certain types of machines by notified bodies

Certain machinery is subject to specific assessment requirements. In the regulation, these machines are referred to as “machinery that has embedded systems with fully or partially self-developing behavior using machine learning approaches that ensure safety functions that have not been placed on the market separately, only in relation to these systems”. This designation comes into play primarily due to the increasing importance of AI and has a direct influence on the risk assessment of machinery.

The following questions, for example, play a role in the risk assessment:

- Can the machine explain to a human why it is doing something?

- Does the machine make safety-relevant decisions?

- How long are these decisions documented?

- Can the machine exceed the actual scope of the task through machine learning?

However, this classification of machines follows technological developments. This means that what does not yet fall into this category today may be included in the next few years. You should therefore always check whether your machine may be affected after all.

As things stand today (2025), the following can be generalized: If your machines work with AI with regard to their safety functions, the assessment must be carried out by a notified body in accordance with the new Machinery Regulation.

3. Reassessment in the event of modifications

The new Machinery Regulation 2023/1230 clearly defines when a new conformity assessment must be carried out for modifications to machinery and systems. This affects not only the manufacturers, but also the operators of the machinery.

If a machine operator makes far-reaching changes to existing machines and systems, they must have a new CE conformity assessment carried out. This is to ensure, for example, that machine modifications that entail an increased risk and require additional protective measures are documented and assessed accordingly.

Machinery that is significantly modified is therefore considered new machinery under the new Machinery Directive. It is irrelevant whether the modifications were made by the manufacturer or the operator. Whoever makes the modifications becomes the manufacturer of the (modified) machine and must therefore carry out the conformity assessment.

4. Covering new risks associated with digital technologies

New digital technologies open up new opportunities, but also entail new risks. Cybersecurity is becoming increasingly important due to the rising level of digitalization. The new EU Machinery Regulation takes this into account.

In the chapter “Protection against corruption”, the regulation defines the requirements for protection against unintentional and intentional IT attacks on hardware and software. It also makes security an obligation for manufacturers. Manufacturers must draw up industrial security concepts and can have their cybersecurity measures certified by notified bodies. Further measures are regulated by the Cybersecurity Act (CRA).

5. reduction of paper-based documentation

To a certain extent, the EU Machinery Regulation 2023/1230 also brings the topic of “sustainability” to the fore with regard to paper-based documentation. In future, machine-related documents can be provided digitally, for example via integrated machine software, enclosed data carriers or online.

For complete machines, this includes the EU Declaration of Conformity and the operating instructions. In the case of partly completed machinery, the EU declaration of incorporation and the assembly instructions can also be made available digitally.

However, consumer goods are an exception. Here, essential safety information for commissioning and use must continue to be provided in paper form.

In addition, the regulation not only regulates the “what”, but also the “how” with regard to availability and access to digital documents:

- Provision period: documents must be accessible online for at least 10 years or for the entire expected service life of the machine.

- Access: Access to the documents must be visible on the machine, for example via a QR code.

- Storage by the user: The user must be able to download, save and print the documents.

- Fail-safe: If the machine, the power supply or the internet fails, the documents must still remain accessible.

And what happens if your customers prefer paper documents? According to the regulation, your customers can still request paper documents and you as the machine manufacturer must provide them with the printed documents free of charge within one month.

Timeline for the new EU Machinery Regulation 2023/1230

June 29, 2023:

The new EU Machinery Regulation is published in the EU Official Journal.

July 19, 2023:

The new Machinery Regulation comes into force in all EU member states.

Effective immediately:

Certain requirements, for example on cybersecurity, can already be taken into account by manufacturers.

until January 19, 2027:

Machinery must continue to be placed on the market in accordance with the Machinery Directive 2006/42/EC.

from January 20, 2027:

Only the EU Machinery Regulation 2023/1230 (deadline regulation) applies.

In future, you as a machine manufacturer can or must provide your customers with all relevant instructions and documents digitally. An appropriate system can provide you with significant support.

And if you don't want to introduce stand-alone software in your company for this purpose, we have a tip for you: our flexible worker guidance system weasl not only supports your employees in assembly, it can also relieve you of tasks arising from the new EU Machinery Regulation. Let's take a look at two specific aspects.

Basis for conformity assessments

With weasl, you create the basis for future conformity assessments, for example through internal production controls. Establish efficient, safe and compliant processes with weasl. Here's what our system has to offer:

- Digital step-by-step instructions: Create qualification-appropriate, context-related instructions with multimedia support and interaction options.

- Documentation and traceability: Record all work during processing to ensure compliance with standards and auditability.

- Quality management and process optimization: Enable data-based decisions with weasl and record reasons for faults.

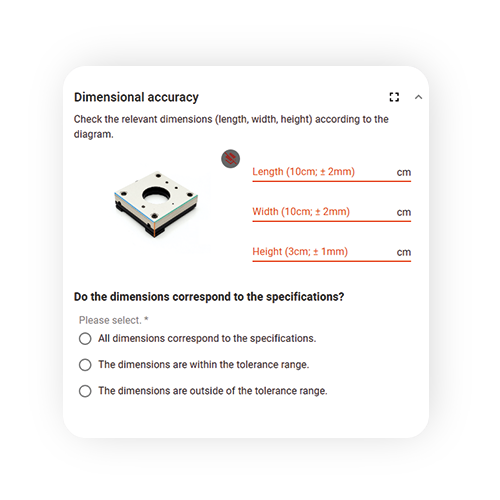

- Integration of testing and measuring devices: Record data automatically and without “translation errors” by connecting testing and measuring devices.

- Compliance with legal requirements: Use weasl to ensure that tests are carried out completely and correctly and automatically document all process steps.

- Feedback and incident reports: Capture feedback in real time and notify the relevant departments of incidents directly from weasl.

Digital operating instructions and assembly instructions

You can easily implement the standardized content of an operating instruction in weasl and prepare it like a digital work instruction. This content can include

- the scope of application

- the area of application

- information on hazards to people and the environment

- technical protective measures

- organizational protective measures

- personal protective measures

- behavior in the event of malfunctions

Record all this data and information in a digital operating manual in weasl, which you make available to your end customers.

Would you like to offer your customers an additional service? Then enrich the instructions with mandatory fields as a read confirmation, video content for better clarification or additional training documents. Your customers then scan a QR code on the machine, for example, and are forwarded directly to the operating instructions in weasl.

If you deliver incomplete machines that still need to be assembled by the end customer, you can also display the assembly instructions digitally in weasl. This allows you to guide your customers step by step to the professionally assembled machine.

When will the new Machinery Regulation come into force?

The new EU Machinery Regulation 2023/1230 comes into force on 20.01.2027 and must be applied when placing machinery on the market from this date.

What changes will the new Machinery Regulation bring?

The EU Machinery Regulation introduces new regulations that take into account the state of the art in terms of digitalization, self-learning systems (AI) and cybersecurity, for example.

It enables smooth interaction with the New Legislative Framework (Guide to European Product Regulation) and includes an updated list of conformity assessment procedures.

For manufacturers and operators, the aim is to reduce the administrative burden as well as costs - for example by using digital formats for operating instructions.

In contrast to the previous Machinery Directive, Regulation 2023/1230 in its current form is binding across the EU. Scope for interpretation and implementation is avoided and legal certainty is increased.

Behind all the adaptations, changes and regulations is the general aim of minimizing risks due to new technologies.

Which devices are affected by the Machinery Regulation?

The new Machinery Ordinance applies to all machinery, partly completed machinery and associated components, as well as software and control systems. Its scope includes, for example

- plastic injection molding machines

- agricultural machinery

- hoists and elevators

- packaging machines

- electrical and electronic equipment

Can existing machinery continue to be placed on the market after the Machinery Regulation comes into force?

No. The previous Machinery Directive 2006/42/EC will cease to apply on 20.01.2027. This means that machines with an EC presumption of conformity with the Machinery Directive may no longer be placed on the market after this date. Machinery must comply with the provisions of the new Machinery Directive from the effective date.

Where can I view the German version of the Machinery Regulation?

You can find the complete text of the new Machinery Regulation 2023/1230 on the European Union website: Regulation - 2023/1230 - EN - EUR-Lex

Conclusion

With the EU Machinery Regulation 2023/1230, a uniform, binding regulation for the sale of machinery, machinery-related products, software and control systems will apply throughout Europe from January 20, 2027. It is intended to take account of the technological developments of recent years and ensure safety and health protection when working with machinery.

You can already prepare for the new requirements today. For example, by using a worker assistance system such as weasl, you can conveniently provide operating instructions digitally in future and also create the basis for internal conformity assessments.

Arm yourself for the demands of tomorrow - with weasl

The new EU Machinery Regulation is a done deal and its requirements will be binding from 2027. Set up the necessary routines and processes now so that you can continue to produce in compliance with standards in the future. In weasl you will find a powerful tool for this.

Experience for yourself what weasl can do - free showcase environment.