December 11, 2023 | Author: Christin Senftleben | Reading time: approx. 5 minutes

Why is knowledge retention important for manufacturing companies?

Knowledge secures the competitiveness of companies. Alongside land, labor and capital, it is one of the most important production factors. In many companies, knowledge now accounts for the largest share of total value added. Experts estimate this share at around 60 percent. Securing knowledge should therefore be seen as a fundamental, permanent task.

When is knowledge retention particularly relevant?

It becomes particularly important when experienced employees leave the company due to age or a change of job. Companies run the risk of losing the assembly, quality inspection and maintenance knowledge they have built up over the years. If successors are also left to their own devices when it comes to training, good advice is expensive. Knowledge retention and knowledge transfer are therefore relevant for every manufacturing company.

What dangers exist if knowledge is not transferred and secured within the company?

Required knowledge is difficult to access and therefore slows down the work process. Productivity decreases.

Knowledge is not used adequately because the people involved are not aware of its potential.

There is a lack of motivation to share knowledge.

Knowledge is lost.

How can knowledge be easily transferred and saved in assembly, quality inspection and maintenance?

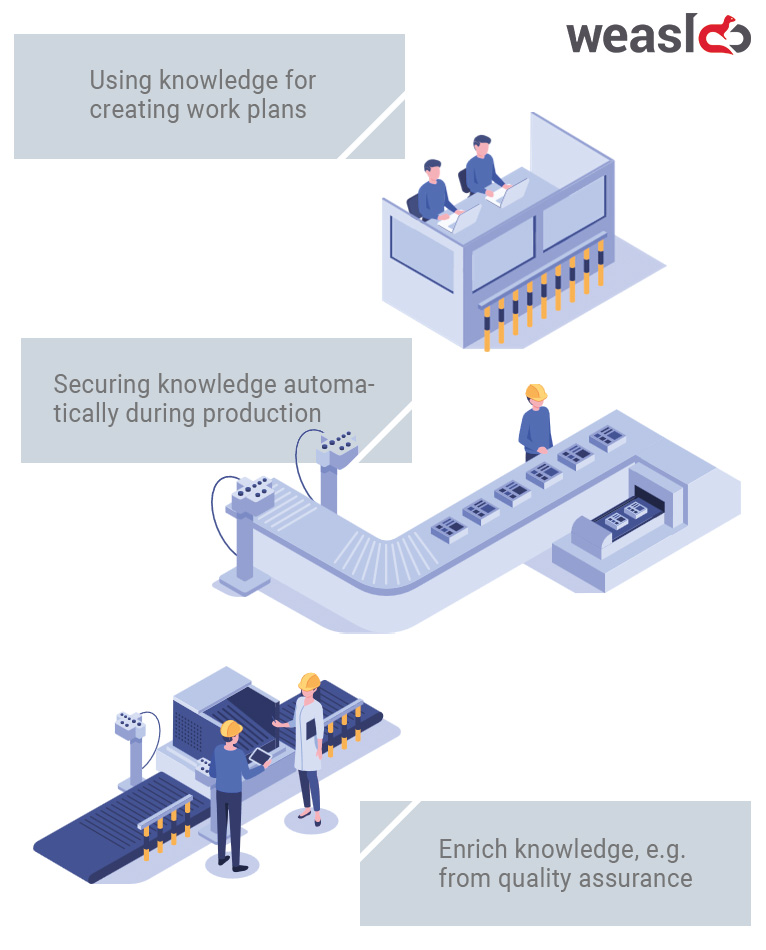

A digital worker guidance system such as weasl enables employees on the store floor to easily store and use performance-relevant information digitally. It supports and promotes the structured transfer of knowledge from knowledge carriers to knowledge recipients. The knowledge is available regardless of personnel changes and is documented in an up-to-date, comprehensible and traceable manner.

How does weasl improve knowledge transfer during ongoing production operations

With the help of the worker guidance system weasl, work processes are described in digital work instructions. The advantage: employees' implicit knowledge, such as experience and knowledge of procedures, is also recorded and flows directly into the description process. Production managers can take execution information into account when making future decisions and design work processes more efficiently. Knowledge is saved, updated and made available in one system. Thanks to the feedback mechanisms, disruptions in the workflow are communicated more quickly. Production managers can react quickly or assign someone to find the cause. In addition, information on production progress, deviations from plan or causes of errors can be passed on to the next shift, production management or sales.

Conclusion

Knowledge transfer is more important than ever in times of demographic change and increasing staff turnover – creating the right conditions in good time ensures the competitiveness of manufacturing companies. Established digital guidance solutions with a clear focus on knowledge retention and knowledge transfer can quickly empower (production) employees for continuous knowledge retention and systematically integrate the process into everyday working life.

Learn more in our webinar

Knowledge retention is the production imperative of the hour. But how do you secure your employees' knowledge in a particularly effective, sustainable and beneficial way? Our worker guidance system weasl provides the answer and we explain exactly how this works in our free webinar "Sustainable production through knowledge retention". Register now.